Quantum RTLS: Inspired by Evolution

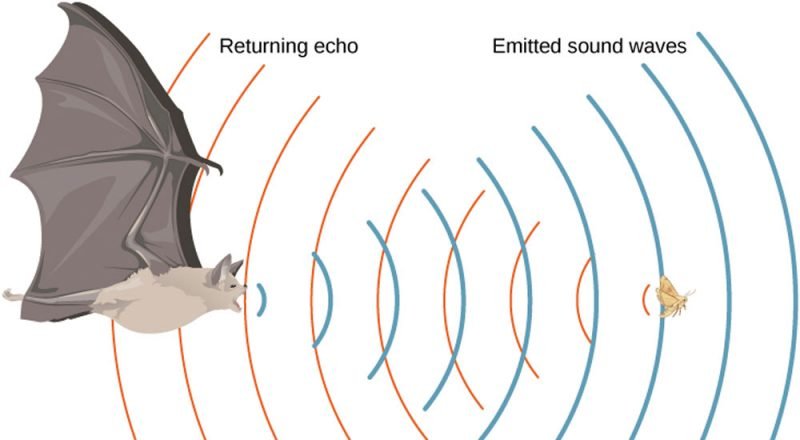

ZeroKey’s breakthrough technology, Quantum RTLS, is a revolutionary millimeter-level 3D real-time location system (often referred to as an indoor positioning system) that helps businesses dramatically improve efficiency, eliminate waste, optimize human-centric workflows and processes, and ensure worker safety and compliance. Leveraging proprietary technology, Quantum RTLS uses a combination of anchor nodes, mobile nodes, and gateways to establish the position of any asset with 1.5mm 3D accuracy. To achieve this unparalleled positioning accuracy, Quantum RTLS Mobile Nodes emit ultrasonic signals while Anchor Devices mounted throughout the facility continuously ‘listen’ in the same ultrasonic frequency. When a signal is detected, the positioning engine uses the time of detection compared to the true time the signal was emitted to estimate the range between the mobile device and the anchor based on the speed of sound. With four or more ranges, the mobile’s position in 3D space can be precisely determined.

Of course, there is more to this story, including advanced signal processing, filtering, and positioning algorithms that, along with our core technology, have led to 30+ patents worldwide. However, the underlying principle that allows us to deliver a positioning accuracy over 100x better than the next best technology is the use of ultrasonic waves to localize any given thing in time and space.

Ultrasonic positioning is significantly more accurate than other systems because the speed of sound is drastically slower than the speed of light. When travelling through the atmosphere, light moves at a staggering 299,792,458 m/s (or about 670,616,629 mph!). On the other hand, sound travels through the air at roughly 300 m/s (about 100,000 times slower). Indoor positioning takes place when a mobile tracker is within a relatively small range of a stationary anchor (typically between 1-10m in a factory setting, for example), so the difference in arrival time of a radio frequency signal between the various anchors is very little. Measuring the time difference of arrival requires the clocks in all anchor devices to be exceptionally well synchronized. Synchronization differences between anchors and other systematic errors lead to inaccuracies in the ranges, resulting in an incorrect final position. While our Quantum RTLS technology must navigate similar synchronization and systematic measurement challenges as any other indoor positioning system, the errors make up a much smaller percentage of the time difference being measured. Therefore, they have significantly less impact on the final position calculations.

Ultrasonic Locating in Nature

Although Quantum RTLS is the only commercially available real-time location system that achieves 1.5mm 3D positioning accuracy, nature beat us to the punch by 53 million years (and perhaps as much as 85 million years) when it comes to using ultrasonics for hyper-accurate localization. It is commonly known that bats use sonic echolocation to navigate their surroundings, but unless you are a professional biologist or a bat enthusiast, that may be the extent of your knowledge. In this article, we take a deeper look at the fascinating world of bat echolocation to shed light on the power and robustness of ultrasonic positioning.

The utility of echolocation is perhaps most apparent when we examine various examples of convergent evolution. Although we will primarily focus on bats, who to the best of our current knowledge, were the first animals to evolve these capabilities, echolocation is also used by toothed whales (such as dolphins, porpoises and sperm whales) and a few cave-dwelling bird species. Within the Chiroptera order of mammals (a.k.a. Bats), it appears that echolocation has evolved more than once. Even though today’s species of bats evolved from a common ancestor that used the larynx to produce ultrasonic pulses, some species in the Rousettus genus (a.k.a. Fruit Bats) subsequently lost their ability. The fruit bats then re-evolved, regaining the ability to echolocate using tongue clicking instead. The earliest known echolocating bat (and the most recent common ancestor to all modern bats) is pinned at 52.2 million years old. Its extremely well-preserved and completely fossilized skeleton demonstrates the morphological adaptations to the larynx that enable the production of ultrasonic pulses. What are some of the key factors that make ultrasonic echolocation so ideal from an evolutionary perspective?

Low Energy Cost of Echolocation

Although bats are capable of emitting calls that exceed 135dB at 10 centimeters, some of the loudest airborne vocalizations in nature, there is very little energy expenditure involved. This is especially important for species of Microchiroptera (tiny, primarily insectivorous bats that can weigh as little as 6 grams). To account for the high metabolic cost of flight, these bats consume hundreds of insects per hour and eat up to 40% of their body weight every night. Prey detection during hunting and in-flight navigation is achieved through echolocation. By analyzing respiratory gas exchange in a controlled experiment, researchers found no difference in overall metabolic cost when bats were actively echolocating. Despite the high intensity of ultrasonic pulses that enable accurate echolocation at distances of up to 10 meters, the total energy contained in a pulse is small. This same feature of ultrasonics is what enables a versatile range of form factors in ZeroKey’s Quantum RTLS product lineup, allowing us to build ultra-compact mobile trackers with a battery life of up to 6 months in some cases.

Diversity of Echolocation Calls

Different species of bats produce a broad spectrum of calls best suited to their environments and behaviours. Short clicks across a large frequency band are used by cave-dwelling bats to navigate obstacles and move through complex cave systems in pitch-black. Bats that hunt in open spaces prefer to use narrowband calls with varied harmonics depending on the size and distance of their prey. For more precise target localization and three-dimensional precision, especially in cluttered environments, broadband calls are favoured. Finally, bats that produce constant frequency signals get the best of all worlds. Not only can they precisely locate targets, but they can also distinguish the size and type of their prey based on small changes in the return signal that results from an insect beating its wings. These bats have even been observed compensating for Doppler shift when searching for moving targets in busy environments by modulating frequency as they change speed. In doing so, the returned signal is identical to their resting call, which allows them to differentiate their ‘voice’ from others in the crowd. This incredible diversity in how ultrasonic signals can be produced demonstrates the future potential for ultrasonic positioning as the technology matures. Ultrasonic fingerprinting will allow for nearly limitless scalability in the number of objects that can be tracked in one place. At the same time, the signal type can also be adapted to fit different use cases across a wide range of environments depending on the desired outcomes.

Bats can Shout or Whisper

The volume of bat calls can vary significantly depending on their environment and prey. For example, some shouting bats emit calls that reach a volume comparable to that of a smoke detector. The advantage of a loud call is that the signal has more energy to reach a surface and bounce back to the bat, meaning it can ‘see’ further away. However, when you shout it is also easier for others to hear you. This has led to the evolution of some species of moths, giving them the ability to sense when a bat is actively locating them so they can quickly maneuver to safety. In turn, the bats that predate these moths have learnt to whisper. By emitting very quiet ultrasonic pulses as they get closer to prey, the bats make it difficult for the moths to detect their presence.

Similarly, the Quantum RTLS product line uses an adaptable listening distance on each ultrasonic device to suit the environment while maximizing efficiency. On a smaller scale, like a workbench, a shorter listening distance means less multipath interference. In contrast, a longer listening distance makes accurate positioning possible in a warehouse or factory with anchor sensors mounted to high ceilings.

Achieving Hyper-Accurate Positioning with Ultrasonics

There is no doubt that bats require precision to perform the tasks necessary for their survival. An astonishing number of insects are consumed by bats – some species eat up to 1000 flying insects per hour by a single individual! To hunt tiny prey in the dark with this success rate is no small feat and is only enabled by the high degree of accuracy inherent to ultrasonic positioning. But just how accurate is ultrasonic positioning? For bats that have the advantage of specialized vocalization adaptations and dedicated neural circuitry, the ability to detect range changes of less than 0.1 millimeters has been demonstrated in multiple controlled experiments.

Similarly, ZeroKey’s Quantum RTLS technology can locate an object in 3D with 1.5-millimeter accuracy. Compared to a bat, this might not seem very impressive. However, it is still over 100x more accurate than the next best indoor positioning technology on the market!

Democratizing Ultrasonic Positioning

Our world is analog, leaving most physical processes inherently invisible to the digital domain.

Just like how bats use ultrasonic echolocation to ‘see in the dark’, Quantum RTLS illuminates industrial environments by digitizing and digitally twinning physical processes with unparalleled precision. Millimeter-accurate positioning enables the real-time digitization of complex, human-centric processes for manufacturing, supply chain, logistics, worker safety and healthcare applications. Using spatial data to track the exact locations of personnel, tools, work orders, and equipment allows for accurate modelling and monitoring of processes, such as kitting a work order or fastening and sequencing bolts on a part. Quantum RTLS is commercially available, easy to deploy, and scalable, putting the power of ultrasonic precision at your fingertips.

To learn more about how Quantum RTLS can digitize, automate, and optimize your operations, schedule a free consultation with one of our RTLS experts today!