SMART MANUFACTURING

SMART MANUFACTURING

Process monitoring & task sequencing with millimeter accuracy

Process monitoring & task sequencing with millimeter accuracy

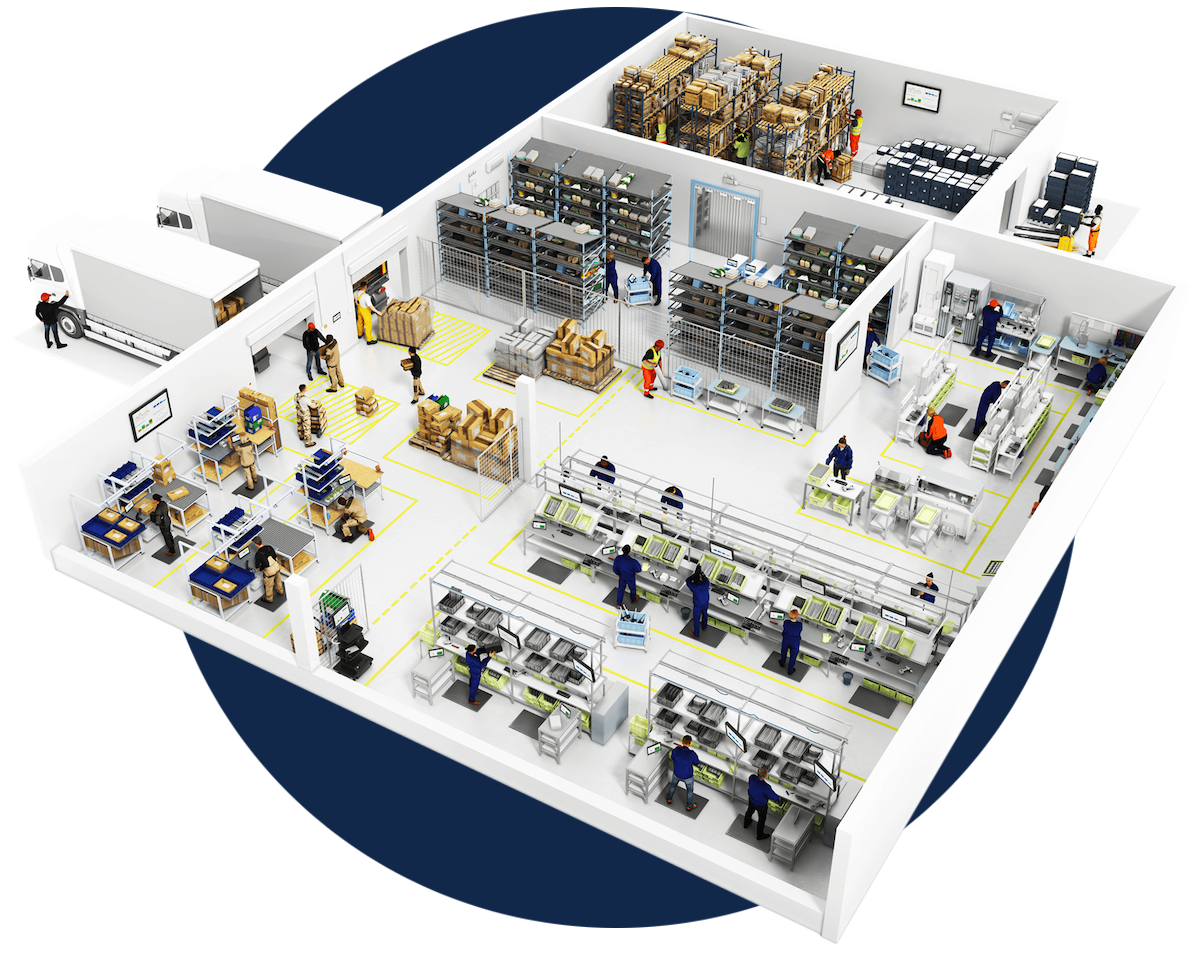

Digitize, Automate & Optimize Processes

ZeroKey’s breakthrough technology, Quantum RTLS 2.0, is a high precision real-time location system (RTLS) for demanding industrial environments. The technology revolutionizes manufacturing processes by digitally twinning operations in real-time with unprecedented accuracy. Quantum RTLS 2.0 offers 1.5mm 3D process tracking and site-wide scalability, making it the leading RTLS for factories.

Quantum RTLS 2.0 is the world’s most accurate industrial RTLS with 1.5mm 3D accuracy. It’s easy to deploy, easy to scale, and offers complete transparency into dynamic operations and processes. The resolution that Quantum RTLS 2.0 brings to dynamic industrial environments enables businesses to:

- Digitize and automate processes.

- Optimize processes and maximize resource utilization.

- Detect anomalies and avoid costly rework.

- Improve floor operations, safety, and compliance.

- Increase productivity and quality control with hyper-accurate 3D real-time process data.

- Eliminate expensive process failures and improve production yield.

- Eliminate time-consuming manual searches and audits.

- Drive optimization and QA/QC.

- Achieve total operational visibility into facility-wide operations.

- Improve quality control, process optimization, and automation.

- Improve process tracking and sequencing with millimeter accuracy.

Above all, Quantum RTLS 2.0 digitizes, automates, and seamlessly integrates manufacturing operations. With ZeroKey’s technology, businesses improve efficiency, reduce costly errors, and boost productivity by verifying that the necessary people, parts, and tools are at the right place at the right time.

ZEROKEY & TULIP

Making Digital Transformation of Complex Manufacturing Processes Easy

Revolutionize your manufacturing operations with an integrated solution that combines ZeroKey’s Quantum RTLS™ 2.0 technology with Tulip’s Frontline Operations Platform. This powerful combination enables seamless process control, complete automation, and the highest level of operational visibility by harnessing millimeter-accurate positioning data to digitally twin your operations and drive Tulip app logic in real-time.

Revolutionize your manufacturing operations with an integrated solution that combines ZeroKey’s Quantum RTLS™ 2.0 technology with Tulip’s Frontline Operations Platform. This powerful combination enables seamless process control, complete automation, and the highest level of operational visibility by harnessing millimeter-accurate positioning data to digitally twin your operations and drive Tulip app logic in real-time.

Traditional location technologies cannot precisely digitize human-centric processes on a large scale, resulting in significant untapped value in production efficiency, worker safety, quality control, and more. The integration of ZeroKey and Tulip offers a digital twin for manufacturing that unlocks this untapped value by automating and digitizing these processes in real-time with unparalleled accuracy across entire facilities. Streamline processes and seamlessly connect physical workflows, track material flow and work orders, respond to incidents, and so much more. With the ZeroKey and Tulip integration, customers gain complete visibility of any process, from human-centric manufacturing to facility-wide order tracking.

Visit our partner page to read more about the Quantum RTLS 2.0 and Tulip integration.

Digitize Human-Centric Processes

Historically, the digitization of complex human-centric processes has been challenging due to the technical limitations of earlier technologies. Traditional technologies like Ultra-wideband and Bluetooth, cannot precisely digitize these processes on a large scale, resulting in very marginal improvements in production efficiency, worker safety, quality control, and more. With the ability to digitize and digitally twin these manual processes with extreme precision in real-time, ZeroKey and Tulip’s integrated solution helps clients realize efficiency gains, and enhanced quality and process control. The level of accuracy that this integrated solution brings to industrial environments dramatically increases production efficiency and operational visibility, enabling customers to maximize their output while reducing costly errors.

Operational Visibility for more Intelligent Decision Making

Achieve total business intelligence with ZeroKey and Tulip. Operational visibility with unprecedented resolution enables more intelligent decision-making to make your operations more agile and productive. Detect bottlenecks and sources of error across entire process chains with customizable no-code Tulip dashboards. With Quantum RTLS 2.0’ ability to digitize any procedure in your workflow, businesses move beyond the one-off optimization of individual processes to the continuous real-time optimization, automation, and integration of their entire facility. Generate KPIs that would otherwise be impossible with conventional IIoT systems, such as real-time insight into productivity at workstations involving made-to-order products. Above all, Tulip and ZeroKey are empowering new levels of operational visibility to maximize your customers’ satisfaction.

Enhanced Process & Quality Control

The ZeroKey and Tulip integration offers real-time quality control and just-in-time process control. Make costly rework a problem of the past by eliminating sources of human error. Define geofenced regions to automatically trigger actions within Tulip apps, enabling process control over an enormous range of supported devices. While the potential use cases are limitless, some current examples used by our customers include:

- ERP software automatically updates when an order moves from a production area to a shipping area.

- Modelling of human-centric workflows enables just-in-time event triggers without any manual input from the worker.

- Live task monitoring for detailed error tracking of incorrect picks and missed steps.

- When an error occurs, corrective feedback is provided to the user instantly, resulting in a highly automated and streamlined quality control process.

Complete Automation

The integration of ZeroKey and Tulip enables clients to digitize, automate, and track the movement and interaction of everything in their workflow. Benefits include:

- User or app-defined geofenced regions automatically trigger tasks and actions, eliminating time-consuming data entry by frontline workers.

- Common data-entry steps such as barcode scanning, loading workorder information, and photo verification are easily automated in any Tulip app.

- Automatic identification of idle orders for redistribution if they do not move within the expected time period.

- Live tracking and monitoring of every order in production, making lost orders a thing of the past.

- A significantly reduced compliance burden with an automated digital audit trail for unmatched traceability.

The ZeroKey and Tulip partnership offers seamless integration of ZeroKey’s Quantum RTLS 2.0 technology, giving our clients the ability to automate order tracking, increase process control, and digitize complex workflows in 3D with unparalleled precision. Together, ZeroKey and Tulip are delivering on the promise of Industry 4.0. Contact us to learn more.

QUANTUM

RTLS 2.0

TECHNOLOGY

Quantum RTLS 2.0 provides 3D millimeter-level position accuracy to track the movement and interaction of everything in your workflow in real-time.

SPATIAL

INTELLIGENCE

PLATFORM

ZeroKey’s Spatial Intelligence Platform is a highly configurable software platform that provides easy access to and analysis of spatial data.

BOOK A SALES CALL

WANT MORE INFO?

DOWNLOAD OUR WHITE PAPER

ZeroKey’s Quantum RTLS 2.0 technology is backed by more than thirty patents and extensive research and development! Want to learn why we’re the most accurate RTLS technology in the market? Read all about it in our white paper.

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3

RESOURCES

SITE MAP

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3