Re-imagining the Operations Tech Stack

with High-Accuracy Location Data

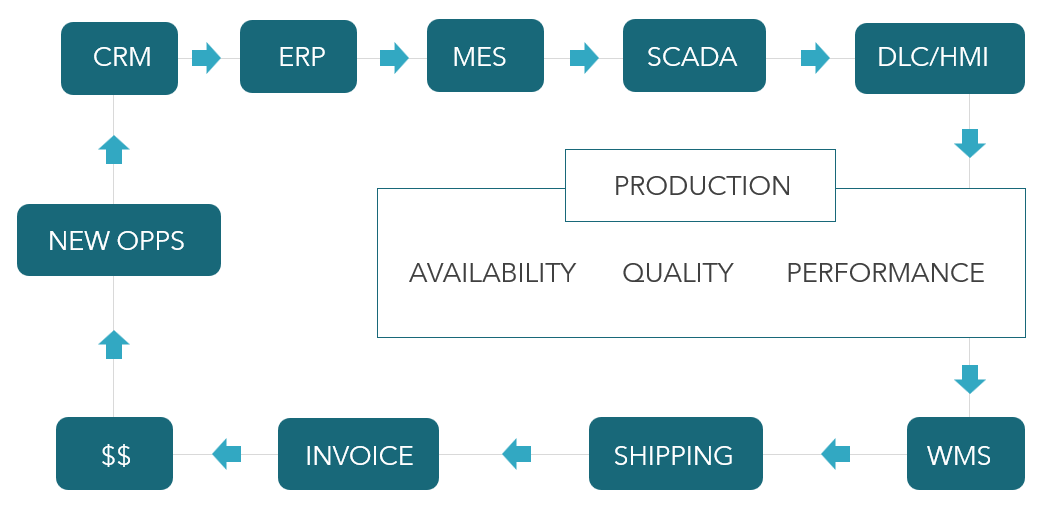

In today’s increasingly competitive world, businesses rely more than ever on an integrated and seamless operations tech stack to optimize their processes and inform critical decision-making. At its core, an operations tech stack includes a combination of systems designed to address specific operational needs and create a cohesive ecosystem that supports the different facets of an organization’s operations.

What is the current tech stack landscape?

The current operations tech stack landscape typically processes new opportunities through sales and resource planning channels which in turn trigger production or fulfillment processes to deliver the required goods and services.

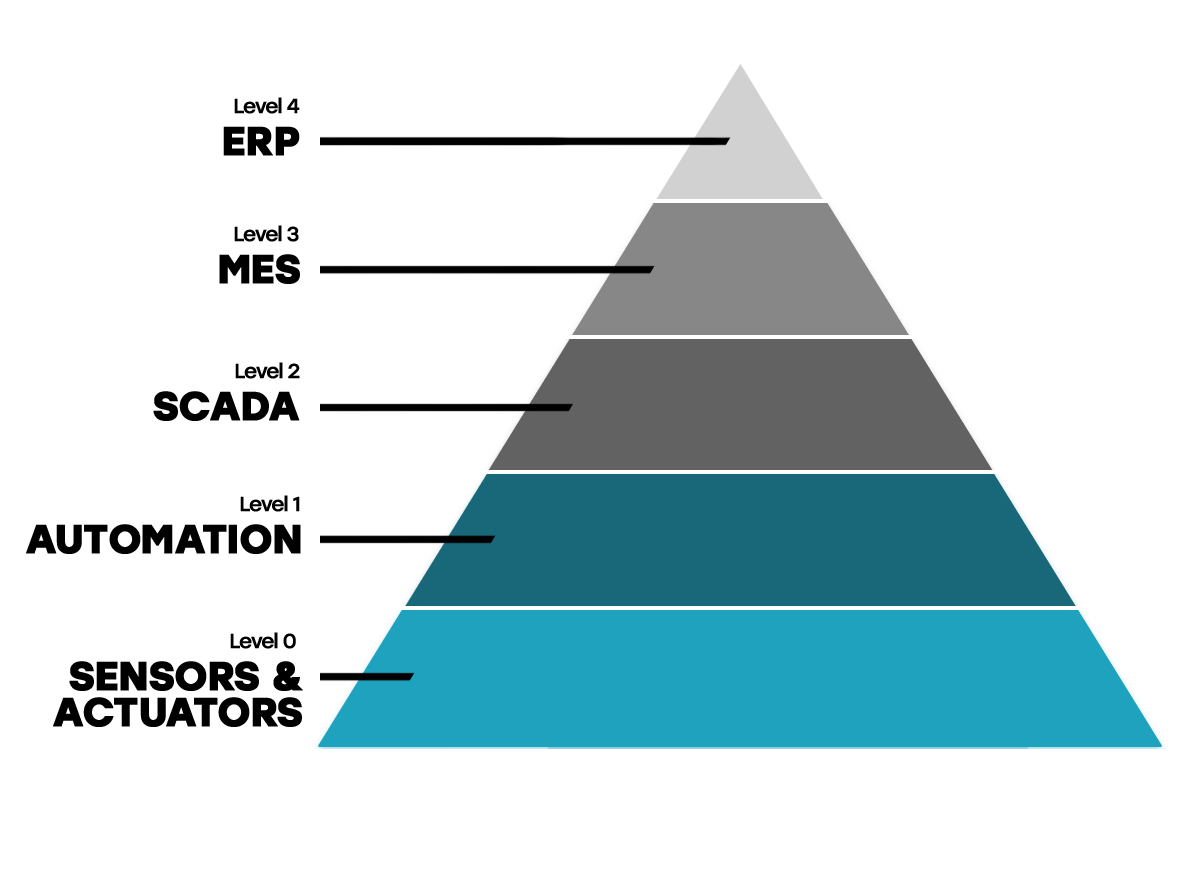

The operations tech stack is often visualized as a pyramid to show how these systems build on each other. At the base of the pyramid, sensors and machines on the shop floor provide the inputs and outputs to the automation systems which in turn integrate the data up the pyramid and ultimately back to ERP systems that are directly used to inform higher-level business decisions.

The Problem

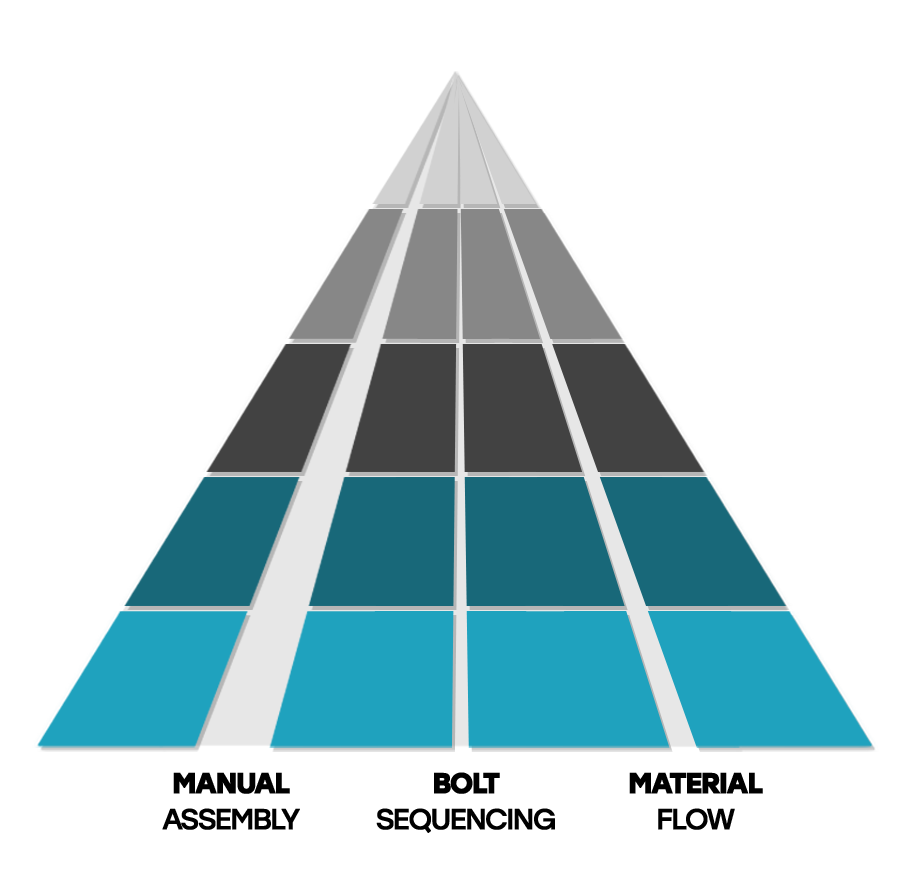

The sensors and systems that make up the base of the pyramid provide very limited monitoring and visibility into human-centric workflows, making process control extremely difficult. The lack of actionable insight into steps such as manual assembly or fastener tightening creates critical information gaps that propagate to the top, resulting in significant untapped value in production efficiency, quality control, worker safety, and more.

The Solution

ZeroKey’s breakthrough technology, Quantum RTLS™, is a hyper-accurate indoor positioning system that offers 1.5 mm 3D resolution in real-time. The technology unlocks the ability to create high-fidelity digital twins that seamlessly integrate physical processes with other systems in the tech stack. Lightweight and low-profile Mobile tags and wearables offer millimeter-level digitization of assets, tools, material, AGVs, and personnel to provide the ultimate in operational visibility for the modern factory. Here are some real-world examples of how Quantum RTLS is filling common gaps in the operations tech stack status quo.

Tool Tracking

A tool-mounted Mobile tag offers complete visibility into each step of a fastener tightening sequence by digitizing the position of the tool as it moves through the process. The spatial data captured by Quantum RTLS drives triggers and logic in a Tulip frontline application to identify errors as they occur and ensure steps are completed successfully.

Warehousing & Supply Chain

Process Control

Lightweight and ergonomic Quantum RTLS wristband sensors digitally twin production stations by tracking the hand movements of workers as steps are completed. With the hyper-accurate data captured by the system, businesses can move beyond the one-off optimization of individual processes to the continuous real-time optimization, automation, and integration of their entire facility.

Real-time data provides complete operational transparency

Real-time visibility of assets, inventory, personnel, tools, and equipment offers unparalleled insight into entire operations. This allows businesses to identify bottlenecks and inefficiencies in their processes, further enabling prompt corrective action and Lean optimization.

Customizable dashboards for operations, management, planning, and executive functions

Spatial data captured by Quantum RTLS enhances business intelligence with intuitive dashboards that display current and historic production throughput and quality control metrics. As a Tulip partner, Quantum RTLS is easily connected to Tulip’s Frontline Operations Platform, allowing users to build customizable dashboards with minimal effort.

Insight into frontline operations and production processes

Centralized capture of analytics for process optimization

Using Quantum RTLS as a single source of truth for key production metrics centralizes the capture of critical information required to guide process optimization. This streamlines the lean process and enables KPIs that would be impossible without the ability to digitize human-centric manufacturing steps with millimeter-level accuracy.

On-premises or cloud-based deployment options

The Outcome

By re-imagining your operations tech stack with millimeter-accurate location data,

you put actionable information in the hands of the people that need it most,

when they need it most, where they need it most.

The Proof

In a recent customer deployment, the Tulip x ZeroKey integration resulted in:

1.85X FASTER ORDER

FULFILLMENT RATE

80% FEWER

FULFILLMENT ERRORS

1.7M POSITIONS

UPDATES PER DAY

4,500 SCAN LOCATION

TAGGED PER DAY

$500,000+ LABOR AND

SPOILAGE COST

SAVINGS ANNUALLY

565% RETURN ON

INVESTMENT ANNUALLY

ZeroKey and Tulip: Delivering on the Promise of Industry 4.0

ZeroKey is proud to have partnered with Tulip by offering seamless integration of Quantum RTLS and Tulip’s Frontline Operations Platform. This gives businesses the ability to rapidly make spatial intelligence captured by Quantum RTLS actionable by triggering events and driving logic within Tulip’s no-code environment. Take advantage of Tulip’s vast library of connector functions, integrations, and template apps and dashboards to connect spatial events to the real world.

Together, ZeroKey and Tulip are re-imagining the operations tech stack to fully deliver on the promise of Industry 4.0.