Real-Time 1.5 mm Tool Position Validation

Achieve 100% Assembly Confidence with Hyper-Accurate Location Tracking

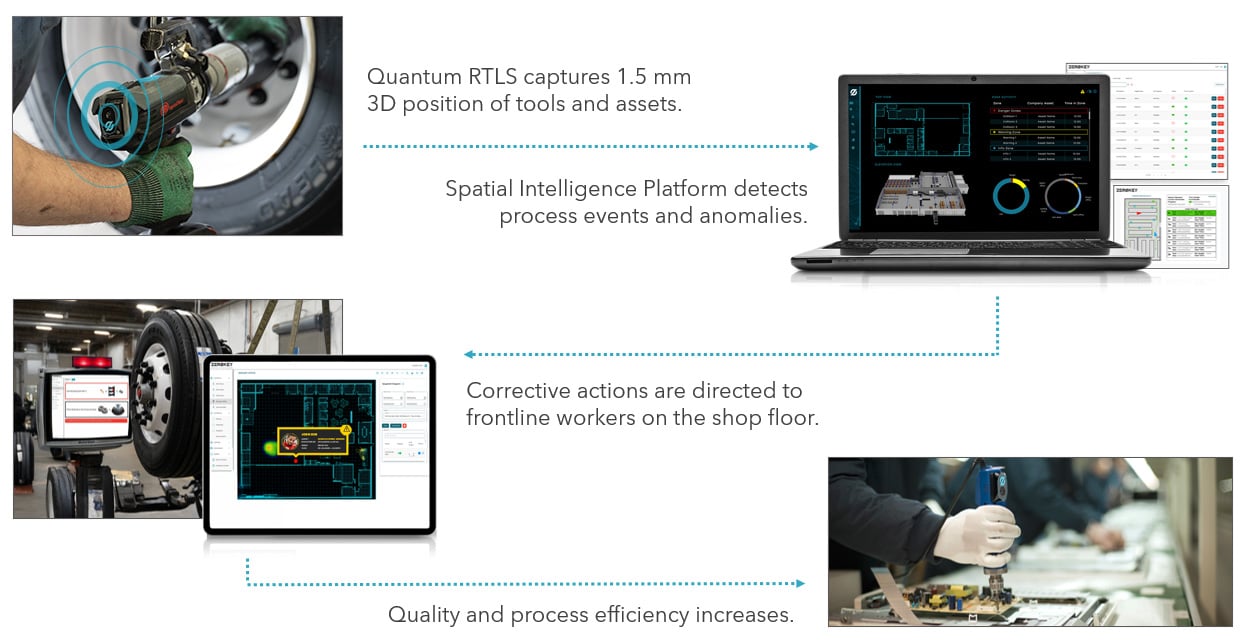

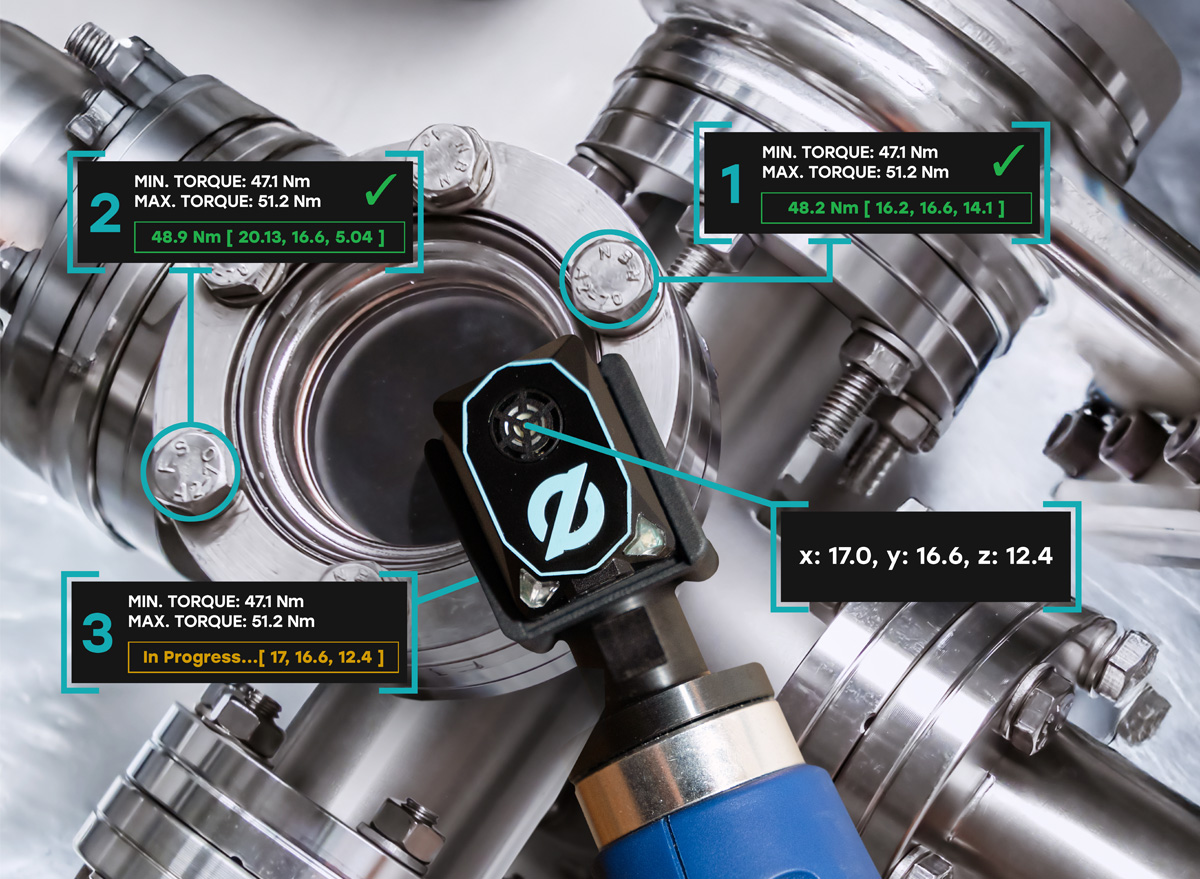

ZeroKey’s Quantum RTLS™ leverages proprietary ultrasonic technology to precisely digitize the real-time position of tools in 3D—down to an industry-leading 1.5 mm in accuracy.

This unparalleled accuracy ensures each bolt is torqued correctly, every time, and that any deviations in process are flagged instantly. The result is complete certainty in build quality, fewer recalls, and improved first-pass yield.

“

The integration with ZeroKey gives us peace of mind. We can confidently say, ‘Yes, every bolt is tightened to specification,’ with data to prove it.

”

Enhanced Accuracy

ZeroKey’s Quantum RTLS ensures each bolt is torqued to the correct specification, eliminating costly rework.

Increased Efficiency

The system reduces the need for secondary verification, streamlining workflows and boosting throughput.

Actionable Insights

Real-time data collection and feedback improve training, ensure compliance, and drive improvement.

Enhanced Accuracy

ZeroKey’s Quantum RTLS ensures each bolt is torqued to the correct specification, eliminating costly rework.

Increased Efficiency

The system reduces the need for secondary verification, streamlining workflows and boosting throughput.

Actionable Insights

Real-time data collection and feedback improve training, ensure compliance, and drive continuous improvement.

Ensure Flawless Assembly Every Time with Ultra-Precise Tool Tracking

By digitizing real-time tool and material movements with millimeter-level precision, Quantum RTLS drives dynamic process control through seamless PLC and MES integrations. In contrast to conventional positioning systems like Ultra-Wideband or RFID, Quantum RTLS is over 100 times more precise—delivering unrivalled certainty for fastener tightening and torque validation.

Automated Torque Selection

Each fastening location is detected in real-time, automatically triggering the correct torque program.

Immediate Error Detection

Out-of-sequence or improper tool usage is identified and communicated instantly to operators.

Deep Process Insights

Generate comprehensive data logs for every tightening event, including time stamps, torque values, and exact 3D tool position.

Eliminate Rework & Protect Your Reputation

ZeroKey’s Quantum RTLS empowers manufacturers with proactive error prevention. Instead of discovering defects after assembly, the system provides instant feedback and tool lockouts, preventing faulty operations from advancing down the line. This hyper-accurate approach improves first-pass yield, significantly reduces the risk of recalls, and builds greater trust with customers.

Real-Time Quality Assurance

Validate each step of the assembly process as it occurs.

Reduced Liability Risk

Generate comprehensive records of every bolt tightening event for audits, warranties, or product liability claims.

Prevent & Resolve Errors Instantly

Automatic tool lockout halts incorrect torque or out-of-sequence actions before they can occur, ensuring no faulty operations advance downstream.

Seamless Integration for Maximum Impact

Quantum RTLS integrates effortlessly with existing manufacturing platforms, including MES and PLC systems, to provide a holistic view of operations. From dynamic tool lockouts to intelligent torque adjustments, plant-floor automation becomes more efficient and responsive than ever before.

API & PLC Connectivity

Easily embed location-driven logic into your existing control architecture.

Flexible Workflow Integration

Adapt Quantum RTLS to established processes without requiring extensive reengineering. Existing processes remain unchanged.

Actionable Analytics

Unlock real-time reporting on performance bottlenecks, operator actions, and overall line efficiency.

Elevate Operational Visibility & Accelerate Throughput

Gain a clear, data-driven view of manual processes to unlock new levels of efficiency. Quantum RTLS captures every operator movement, tool action, and material flow with millimeter-level precision, pinpointing bottlenecks and guiding strategic improvements that increase output while simultaneously improving quality.

Identify Bottlenecks Instantly

Real-time location data reveals exactly where and why slowdowns occur.

Optimize Manual Workflows

Hyper-accurate insights into operator interactions drive informed adjustments for faster, safer processes.

Data-Driven Throughput Gains

Streamline production steps, reduce downtime, and confidently ramp up production.

Frequently Asked Questions

Quantum RTLS continuously tracks the 3D position of each torque tool, comparing its location against predefined sequences and torque values. If a bolt is tightened out of order or with the wrong specification, the system instantly flags it and alerts the operator.

ZeroKey’s proprietary ultrasonic technology achieves 1.5 mm 3D accuracy, exceeding the precision of Ultra-Wideband, Bluetooth®, or RFID solutions by over 100 times. This unprecedented accuracy ensures real-time validation of even the smallest movements.

Any deviation—such as incorrect order, torque mismatch, or skipped steps—triggers an immediate customizable alert event and/or tool lockout (if combined with a compatible Torque Open Protocol smart tool). This allows operators to correct mistakes on the spot, minimizing rework and protecting product quality.

Yes. Quantum RTLS works with a wide range of smart torque tools, allowing seamless adjustment of torque values and immediate tool lockout or release based on precise tool position.

In some cases, jigs or markings may be required to ensure that the workpiece is in a known, repeatable position each time a new part is built. Alternately, if the workpiece itself is tracked jigs are no longer needed as the system can identify the bolt locations based on the real time position of the workpiece.

Absolutely. Quantum RTLS is designed for scalable deployments—from single workstations to entire production floors. Its modular architecture supports expansion without compromising accuracy or performance.

All data captured by Quantum RTLS is encrypted and stored securely. Access controls and robust networking practices ensure only authorized personnel can view or export sensitive production data. The system can operate completely offline, meaning all the data collected remains entirely on-prem.

Although exact timelines vary, many customers report immediate reductions in rework, scrap, and recall risks. Over the longer term, consistent improvements in first-pass yield and tighter quality control drive substantial ROI.

Initial setup and operator training are straightforward. Operators quickly adapt to real-time feedback, and our support team provides ongoing assistance to ensure seamless integration into existing workflows.

Book a Sales Call

WANT MORE INFO?

DOWNLOAD OUR WHITE PAPER

ZeroKey’s Quantum RTLS 2.0 technology is backed by more than thirty patents and extensive research and development! Want to learn why we’re the most accurate RTLS technology in the market? Read all about how we do it in our white paper.

RELATED ARTICLES

ZeroKey Selected by Volkswagen as a Top Exhibitor of Hannover Messe 2024

ZeroKey was honoured to be selected by Volkswagen as a top exhibitor of Hannover Messe…

Read more

Re-imagining the Operations Tech Stack with High-Accuracy Location Data

In today’s increasingly competitive world, businesses rely more than ever on an integrated and seamless…

Read more

10 Ways to Improve Manufacturing Operations with an RTLS

A real-time location system (RTLS) is an essential tool for businesses that want to improve manufacturing…

Read more

Empowering Frontline Workers through Digital Transformation

The Benefits of Empowering Frontline Workers with Digital Tools and Technologies Digital…

Read more

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3

RESOURCES

SITE MAP

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3