Track Materials, WIP, and More with 1.5 mm Accuracy

ZeroKey brings true spatial awareness to your operations. With millimeter-accurate 3D positioning and ultra-low-power tags lasting up to two years, you gain a live digital twin of your material flow to eliminate inefficiencies, prevent loss, and connect every asset to the data that drives your business forward.

2.5mm Galvanized Steel Coil

3.0mm Hot-Rolled Steel Coil

1.8mm Cold-Rolled Coil

4.0mm Pickled & Oiled Coil

2.2mm Stainless Coil

The Problem

80% of warehouses still operate manually with little to no automation. Barcode and RFID systems only provide point-in-time snapshots, leaving blind spots that result in lost material, inventory shrinkage, and business interruption.

The Solution

ZeroKey’s system creates a continuous digital chain of custody. Every movement is captured automatically and integrated into supply chain systems, eliminating human error, lost material, and the need for manual data entry and product scans.

Complete Visibility,

Real ROI

With millimeter-accurate precision, ZeroKey transforms physical location data into actionable intelligence that uncovers inefficiencies, reduces search time, and cuts costly idle inventory.

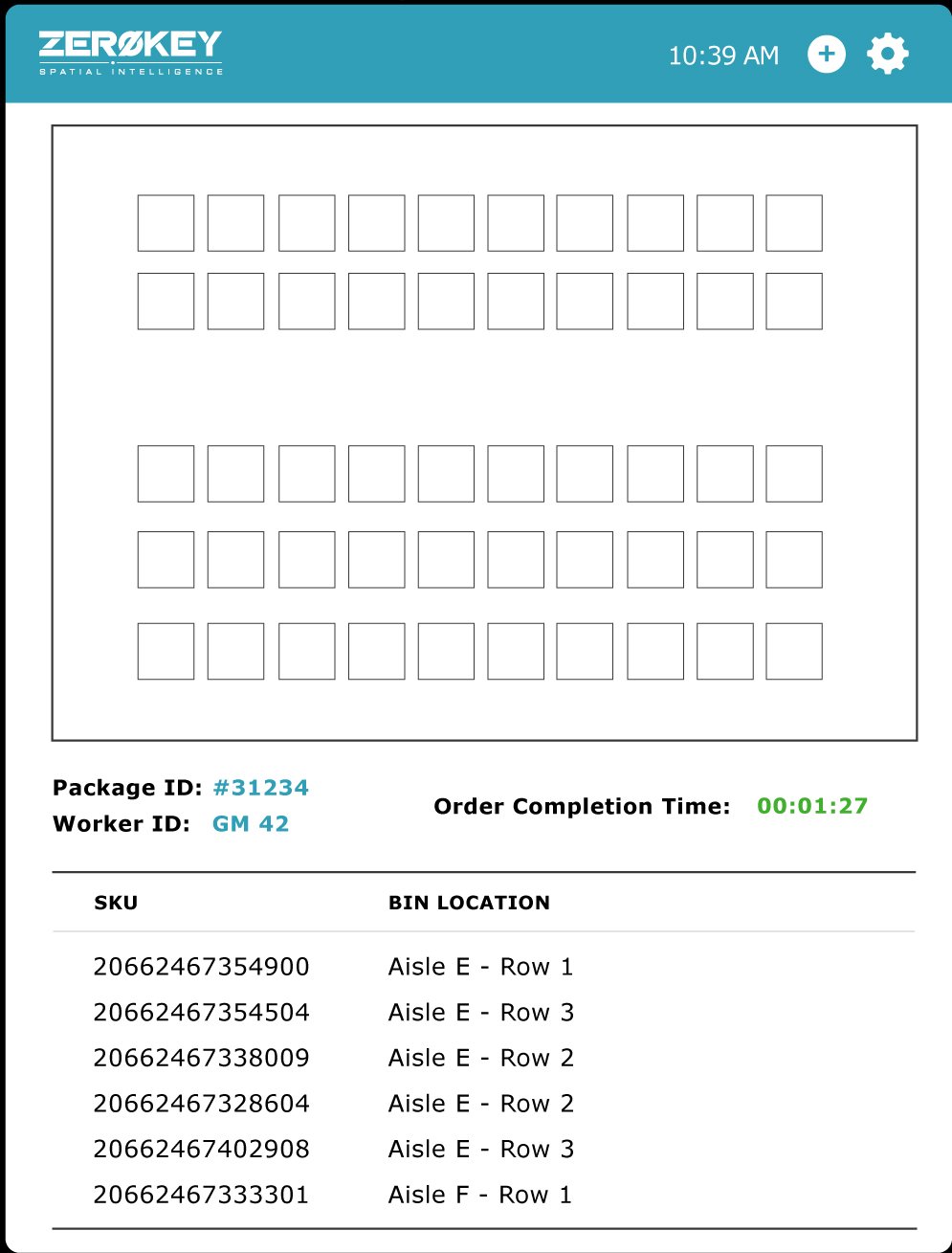

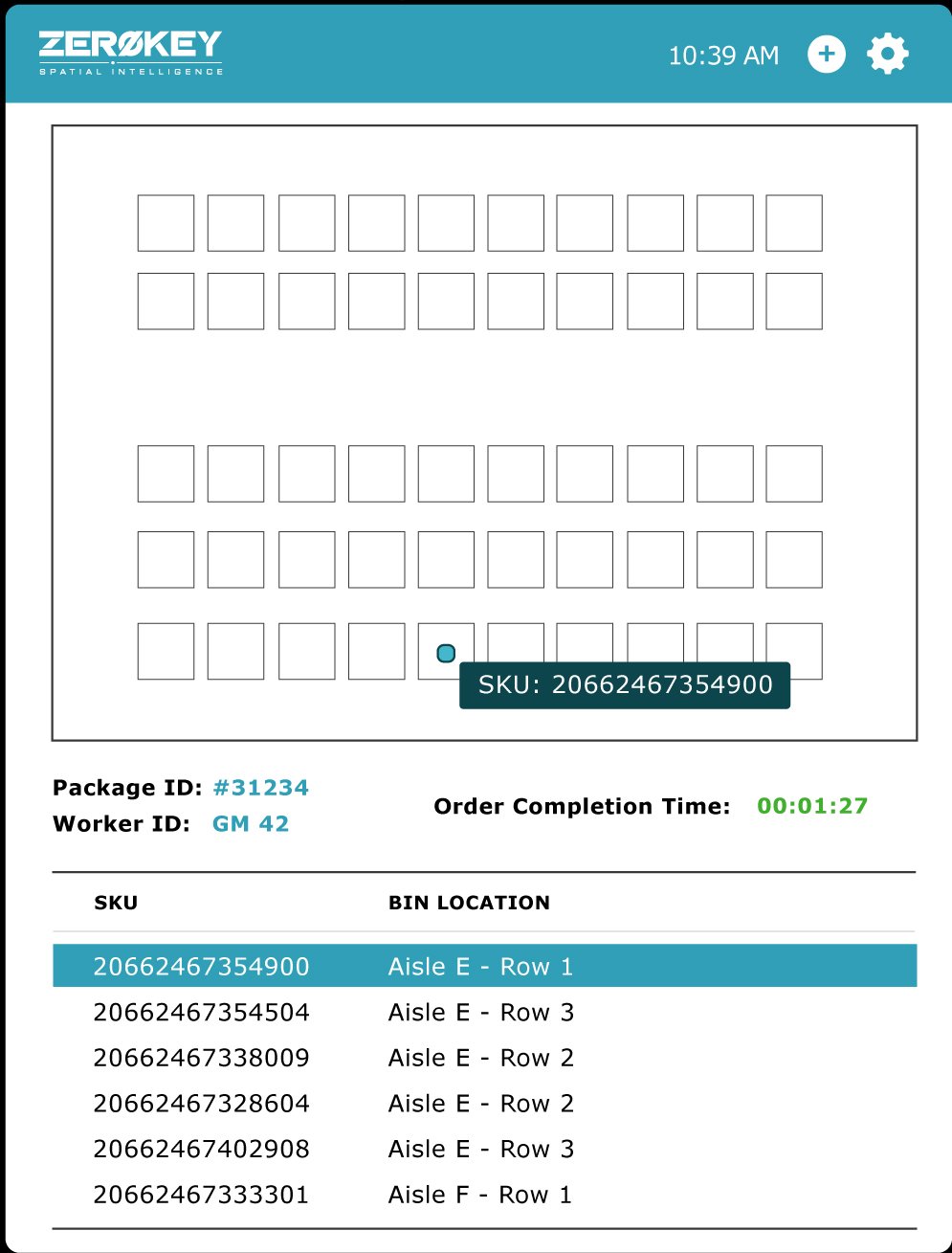

Flexible

Integration

Use ZeroKey’s Spatial Intelligence Platform to create picklists, ping assets, and visualize your floor in 3D, or integrate movement data directly into your MES, WMS, or ERP through our open API.

Instant Insight,

Real-World Impact

Ping any asset in seconds and know its exact location with unmatched precision. Detect delays, restock proactively, and keep materials flowing smoothly with no blind spots or manual checks.

Audit-Ready

Traceability

Every movement is automatically recorded and timestamped, giving you a complete, verifiable history for compliance, quality audits, and continuous improvement, without the burden of manual logs.

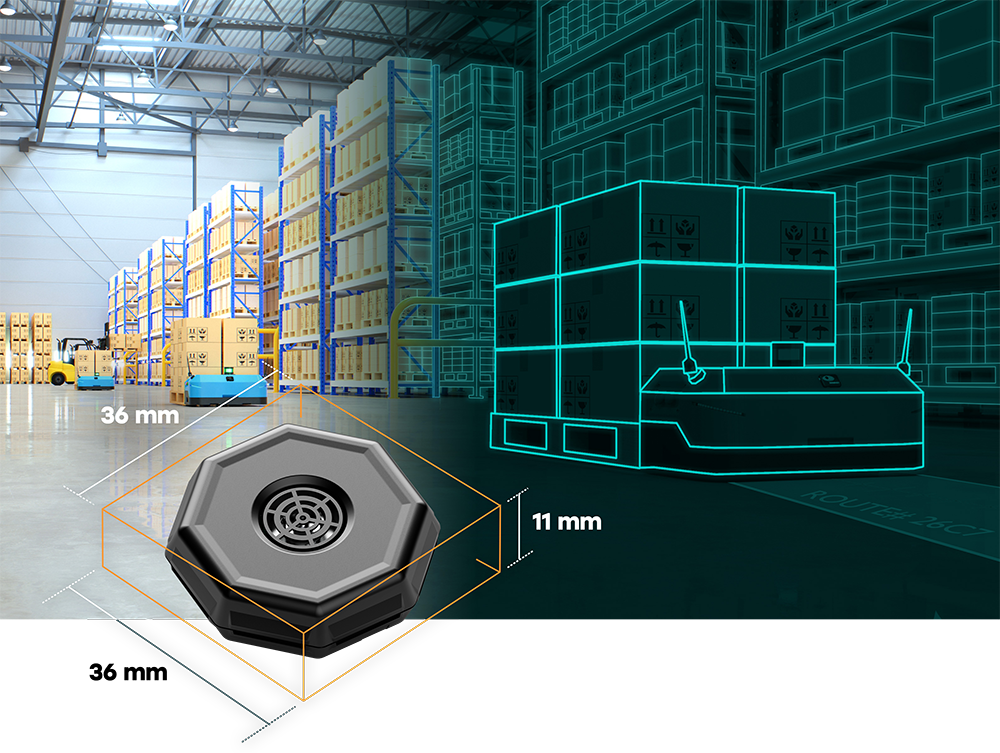

Wall-to-Wall 3D Material Intelligence

Powered by over 30 global patents, ZeroKey’s Quantum RTLS™ 2.0 transforms your physical environment into a continuous digital map that is accurate to within 1.5 millimeters. Every tagged asset is tracked in real-time, creating a live 3D model of your operations that updates with every movement.

Unlike legacy positioning systems, ZeroKey captures full 3D spatial data across your facility, delivering uninterrupted visibility even as materials move through racking, corners, or dense industrial layouts. This results in a seamless, always-accurate digital twin of your material flow in any environment.

Every Movement Logged in Real-Time

ZeroKey continuously tracks every item in motion, automatically recording each transfer as it happens. Every second of movement becomes usable data for unlocking process optimization, traceability, and complete visibility across your material flow.

Integrate precise location and movement data directly into your WMS, ERP, or MES through ZeroKey’s open API, or use built-in automation logic to trigger alerts and optimize workflows instantly.

From Material Tracking to Self-Optimizing Operations

OmniVisor AI™ transforms ZeroKey’s millimeter-accurate location data into real-time operational intelligence. By continuously analyzing the movement (or lack thereof) of every tagged asset, OmniVisor AI automatically identifies idle orders, stalled materials, and process deviations across your facility.

Instead of sorting through data or waiting for reports, teams can simply ask, “Which orders haven’t moved in the past hour?” and see the answer instantly visualized directly on the ap. OmniVisor AI doesn’t just detect inefficiencies; it recommends corrective actions, helping teams rebalance workloads, clear bottlenecks, and keep production flowing smoothly.

From Lost Carts to Lean Flow: 70% Less Search Time with Real-Time Visibility

The Challenge

A leading industrial manufacturer struggled to locate in-process carts and materials across a 150,000 sq. ft. facility. With over 500 mobile carts circulating between stations, operators routinely lost time searching for missing work-in-progress (WIP), and production planners lacked real-time visibility into where jobs actually were. Manual updates to SAP were slow and inconsistent, creating scheduling inefficiencies and layout blind spots.

The Solution

Using ZeroKey’s Quantum RTLS 2.0™, each cart was equipped with a low-power tag that automatically reports its exact 3D position at 5 second intervals when moved. The system updates SAP automatically in real-time as WIP moves in and out of geofenced zones around workstations, eliminating manual scans and ensuring every item’s location is always known. The result is a live, millimeter-accurate digital map of production that enables smarter routing, faster retrieval, and continuous process improvement.

The Impact

With continuous visibility into material flow, the manufacturer:

70%

Reduced search time by 70% across production teams through instant, map-based location tracking

33%

Improved floor layout efficiency by 33%, optimizing station placement and traffic flow using movement data

18%

Cut unplanned downtime by 18% by eliminating delays from misplaced or stalled carts

WANT MORE INFO?

DOWNLOAD OUR WHITE PAPER

ZeroKey’s Quantum RTLS 2.0 technology is backed by more than thirty patents and extensive research and development! Want to learn why we’re the most accurate RTLS technology in the market? Read all about it in our white paper.

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3

RESOURCES

SITE MAP

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3