Introducing OmniVisor AI™: Revolutionizing Manufacturing

Factories have always been the beating heart of innovation. From Ford’s moving assembly line to the dawn of Industry 4.0, every leap has made production faster, smarter, and more efficient.

With the launch of OmniVisor AI, we’re witnessing the next leap forward where the factory itself becomes intelligent.

OmniVisor AI is more than a chat interface. It’s the culmination of years of industrial spatial intelligence experience at ZeroKey, powered by Quantum RTLS 2.0™, the world’s most accurate real-time location system. By digitizing physical movement with 1.5-millimeter 3D accuracy, Quantum RTLS gives OmniVisor AI the data foundation to do something truly transformative: enable factories to self-diagnose inefficiencies and self-correct in real-time.

From the Assembly Line to the Self-Aware Factory

When the assembly line was introduced, it revolutionized production by synchronizing human motion with machine rhythm. A century later, OmniVisor AI synchronizes every element of the factory itself. It understands your facility end-to-end, anticipating problems before they affect output.

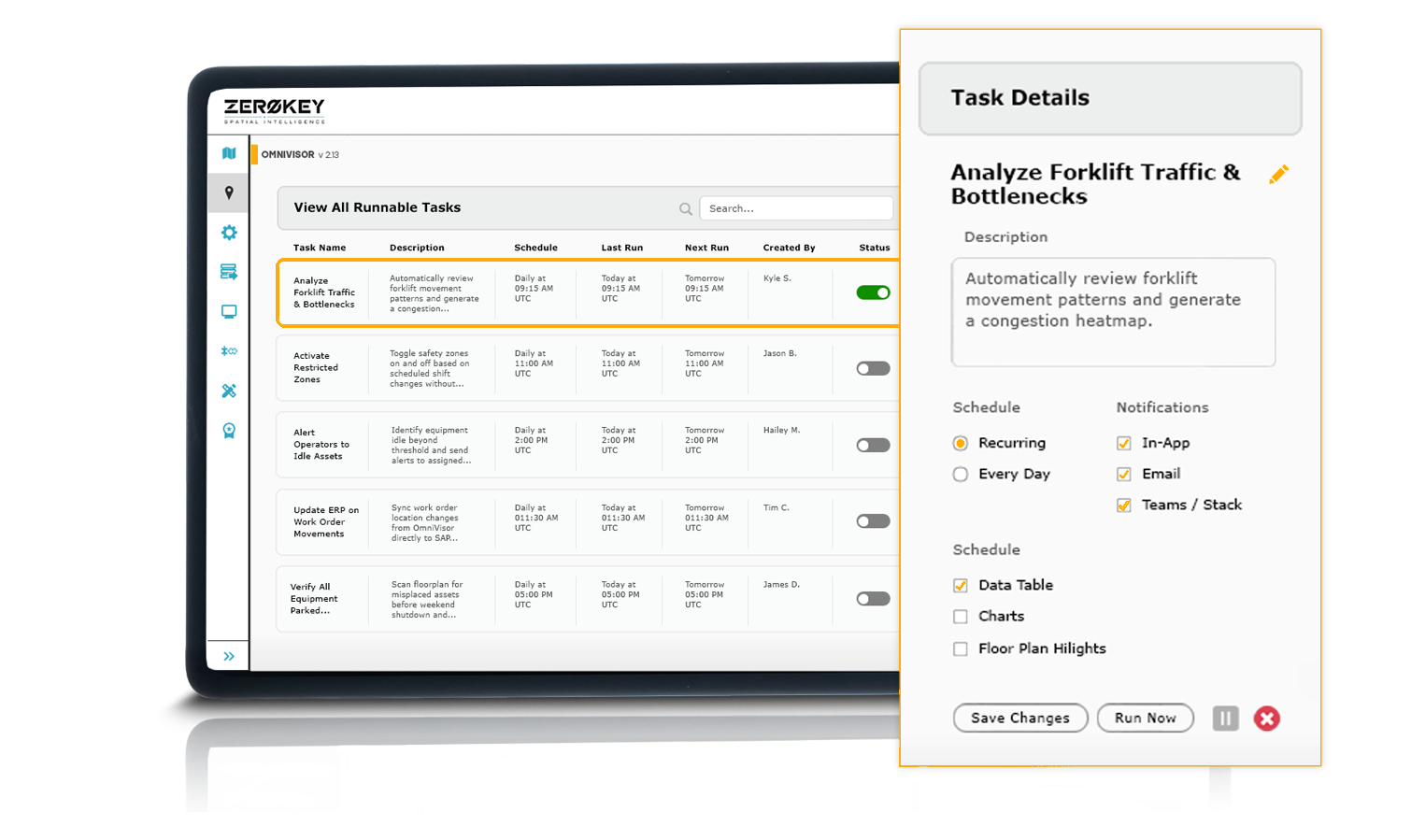

Every tool, pallet, or operator movement becomes a digital signal in a continuous spatial stream. OmniVisor AI reads and reasons over those signals in real-time, using reinforcement learning and large language models to find inefficiencies, predict slowdowns, and act automatically.

Seeing the Invisible

Factories generate oceans of data, but historically, it’s been siloed and static. OmniVisor AI changes that by combining the granularity of millimeter-accurate location tracking with AI-driven reasoning. It enables manufacturers to:

- Visualize Flow Instantly: Create live spaghetti diagrams and heatmaps of operator and equipment movement to reveal hidden inefficiencies, such as congestion or overtravel, in real-world workflows.

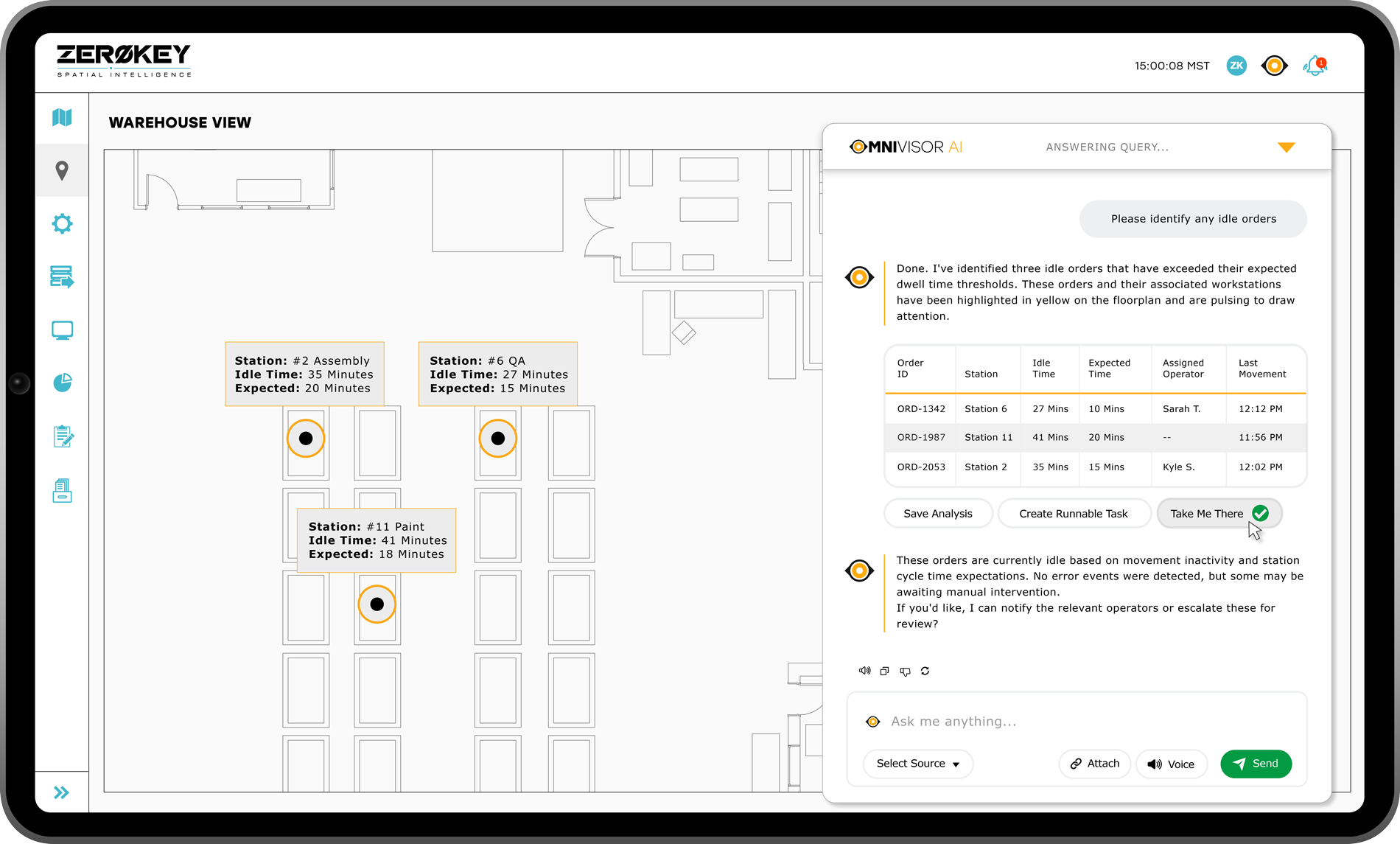

- Spot Idle or Delayed Orders: Automatically detect stalled materials, inactive stations, or underutilized resources and highlight them directly on the map.

- Diagnose Process Drift: Identify subtle deviations such as torque calibration drift, skipped assembly steps, or unbalanced workloads before they impact quality or throughput.

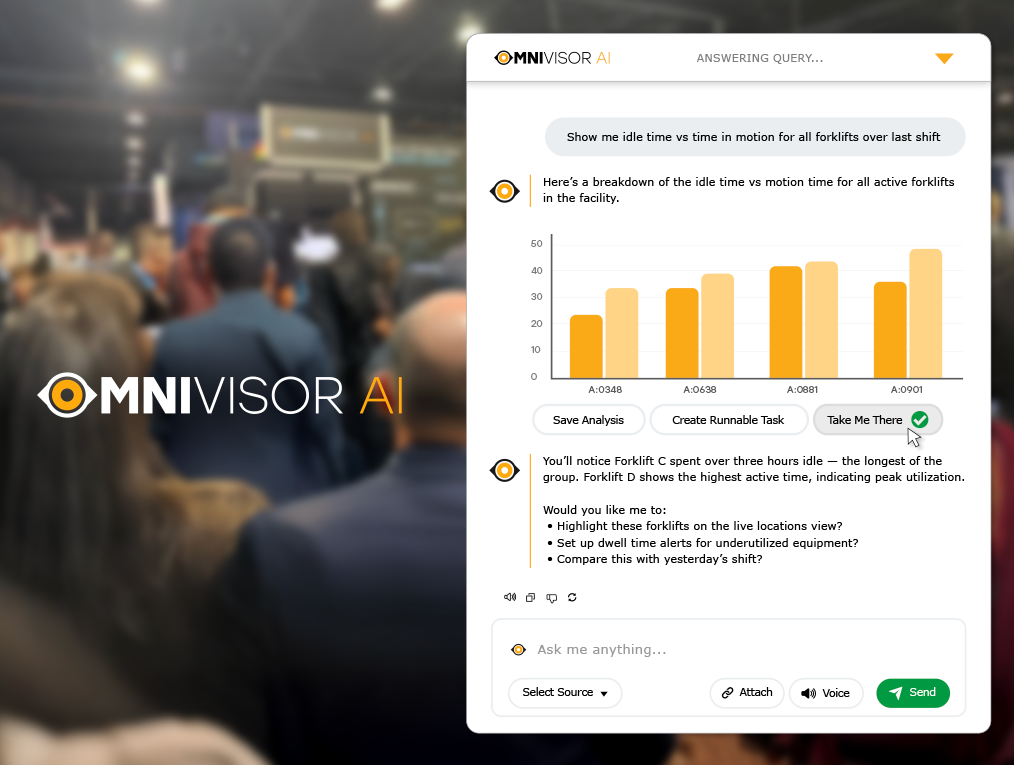

- Deliver Insights in Natural Language: Convert millions of spatial data points into clear, actionable recommendations their team can act on immediately.

- Continuously Self-Optimize: Learn from every shift and adapt to evolving production patterns, ensuring their factory runs smarter, safer, and leaner.

Each of these capabilities represents more than insight. It’s the dawn of human-AI collaboration on the factory floor, where natural language becomes the new control interface for industrial intelligence.

Why Now?

Modern factories generate more data than humans can possibly process. Quantum RTLS sensors capture thousands of millimeter-accurate 3D position events per second—far beyond what traditional data pipelines can interpret in real-time. OmniVisor AI bridges that gap, allowing factories not only to measure what’s happening, but also to understand why. This is what turns visibility into agency, allowing the factory to act on its own insights.

A Factory That Thinks in 3D

At its core, OmniVisor AI is the interface for a new kind of manufacturing intelligence. It transforms ZeroKey’s real-time positioning capabilities into an agentic intelligence engine that continuously monitors, predicts, and optimizes.

Imagine a system that:

- Knows the exact position and state of every asset, tool, and person in motion.

- Detects inefficiencies the instant they emerge and before they cascade.

- Communicates those insights in natural language and acts on them proactively.

OmniVisor AI monitors every input and output to create a living model of the factory, capable of learning from its own performance.

The Beginning of Autonomous Operations

The launch of OmniVisor AI™ represents a fundamental shift in the future of automation where data is no longer passive. Instead of dashboards that tell you what happened, OmniVisor AI gives you a dialogue with the factory, becoming a true co-pilot for operations that can reason, respond, and act.

Factories that once relied on reports and intuition can now operate on real-time intelligence.

OmniVisor AI is now available.