Your Single Source of Truth for Time and Motion Data

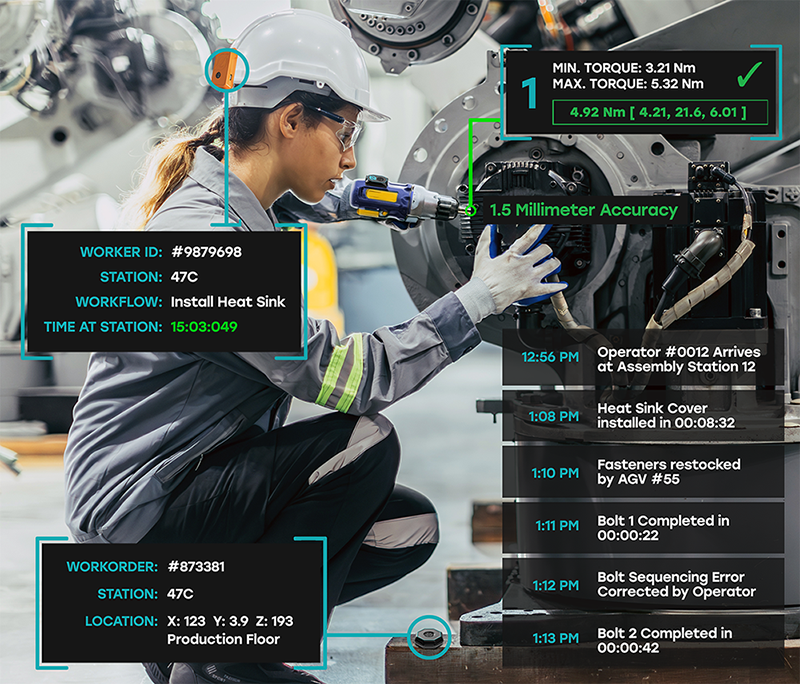

Only ZeroKey’s Quantum RTLS™ + OmniVisor AI™ provide millimeter-accurate time and movement data, creating a single source of truth for workforce efficiency and process flow. Unlike manual logs or less precise systems, 1.5 mm spatial intelligence captures what no other technology can: every task, transition, and delay in real time.

The Problem

Manual labor tracking is slow, error-prone, and incomplete. Stopwatches, PLC timers, and manual logs can’t capture the real complexity of human-driven processes.

The Solution

Quantum RTLS™ + OmniVisor AI™ automatically recognize every worker movement and task transition with millimeter accuracy, delivering precise, reliable, and actionable labor time data in real-time.

Labor Efficiency

Track actual vs. expected cycle times automatically.

Up to 20% reduction in lost labor hours

Bottleneck Detection

Pinpoint delays at stations, tools, or material handoffs.

Identify issues 3x faster than manual audits

Trusted Data for Teams

Replace manual logs with transparent, verified records.

95%+ accuracy in event recognition

Smarter Planning

Spot risks early and rebalance workflows proactively.

Reduce overtime by up to 15% per shift

Track Every Action, Every Second

ZeroKey automates time-and-motion capture with millimeter-accurate wearables that continuously log operator actions across every cycle. Instead of coarse “time at station,” you get step-level timestamps for assembly tasks, powering live cycle analytics while eliminating manual logging noise and other sources of variance.

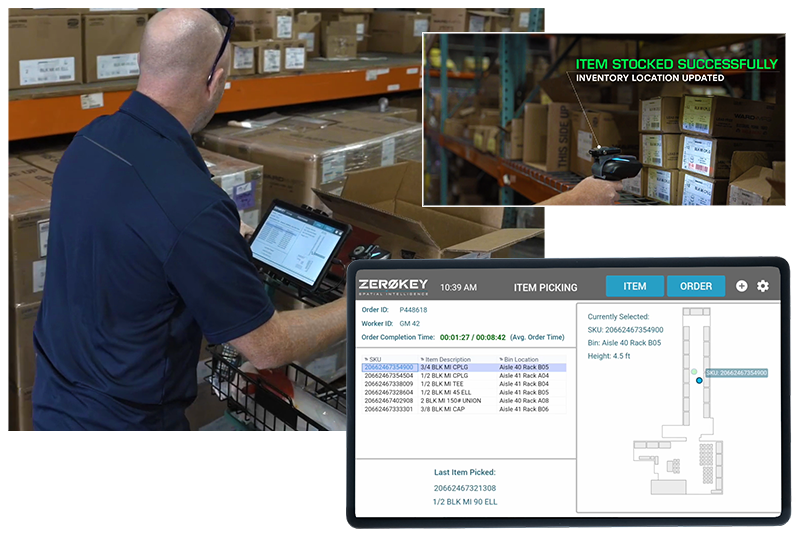

Track Every Work Order, Every Step of the Way

With millimeter-accurate Quantum RTLS™ fused with OmniVisor AI™, every movement of a work order is automatically recognized as it flows across stations. From time spent at each workstation to delays in transit, the entire labor journey is captured and contextualized as it occurs. Labor time recognition becomes a living timeline that is precise, automated, and actionable.

Millimeter-Accurate Time & Motion Study

OmniVisor AI™ + Quantum RTLS™ capture labor activity in dynamic, real-world environments, not just linear production lines. In facilities where workers move between tasks and orders, every interaction is measured and contextualized, building a single source of truth for labor projections. From setup and transit times to actual work execution, every factor that impacts efficiency and profitability is visible in real time.

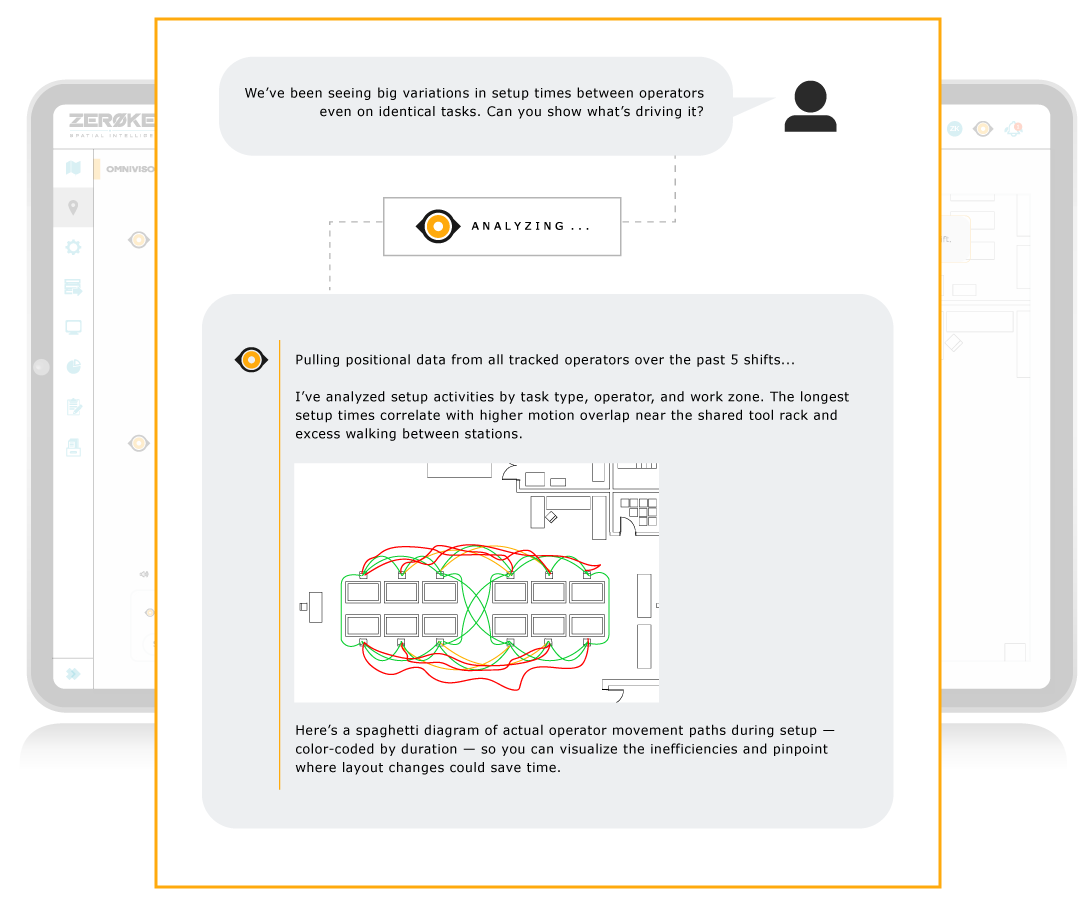

Natural Language, Operational Intelligence

OmniVisor AI™ turns millimeter-accurate labor tracking into insights you can access instantly—just by asking.

- Ask Naturally: Query your factory in plain language, no data pipelines or dashboards required.

- Get Clear Answers: OmniVisor AI™ responds with visualizations, charts, and maps contextualized to your operations.

- Act Immediately: Every answer is actionable: save it, share it, or turn it into a runnable task.

- Always On: With continuous monitoring, insights keep flowing—even before you know what to ask.

Real Results: 565% Annual ROI in Logistics Fulfillment

The Challenge

A global fulfillment provider struggled to understand true labor costs. Manual time studies and rough estimates left blind spots in how workers’ time was spent across picking, packing, and staging.

The Solution

With Quantum RTLS™, every task transition and worker interaction is recognized with millimeter accuracy. Instead of broad time buckets, the system captures the exact moment each discrete action occurs: picking a part, moving to the next station, or staging an order. This transforms raw movement into a precise, continuous record of labor time across every micro-step in fulfillment, giving the company a complete, real-time picture of how work truly happens.

The Impact

By optimizing routes, rebalancing staff, and cutting unnecessary overtime, the company achieved 565% annual ROI without adding headcount or sacrificing throughput.

Faster Fulfillment

Rate

80%

Fewer Fulfillment Errors

6x

Faster New Hire Onboarding

$433,000+

Labour and Spoilage Cost Savings Annually

565%

ROI Annually

The Challenge

A global fulfillment provider struggled to understand true labor costs. Manual time studies and rough estimates left blind spots in how workers’ time was spent across picking, packing, and staging.

The Solution

With Quantum RTLS™, every task transition and worker interaction is recognized with millimeter accuracy. Instead of broad time buckets, the system captures the exact moment each discrete action occurs: picking a part, moving to the next station, or staging an order. This transforms raw movement into a precise, continuous record of labor time across every micro-step in fulfillment, giving the company a complete, real-time picture of how work truly happens.

The Impact

By optimizing routes, rebalancing staff, and cutting unnecessary overtime, the company achieved 565% annual ROI without adding headcount or sacrificing throughput.

Why ZeroKey is Different

Other positioning systems lack the resolution required for reliable time and motion studies. Vision-based systems, for example, struggle with obstructions, changing light conditions, and privacy concerns. ZeroKey’s Quantum RTLS™ is the only positioning system on the market that delivers true millimeter accuracy at scale, providing complete facility-wide coverage so every movement is captured with unmatched precision and reliability.

WANT MORE INFO?

DOWNLOAD OUR WHITE PAPER

ZeroKey’s Quantum RTLS 2.0 technology is backed by more than thirty patents and extensive research and development! Want to learn why we’re the most accurate RTLS technology in the market? Read all about it in our white paper.

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3

RESOURCES

SITE MAP

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3