How The Hacksmith’s “ZeroDOP” Studio Embodies the Future of Human-Responsive Environments

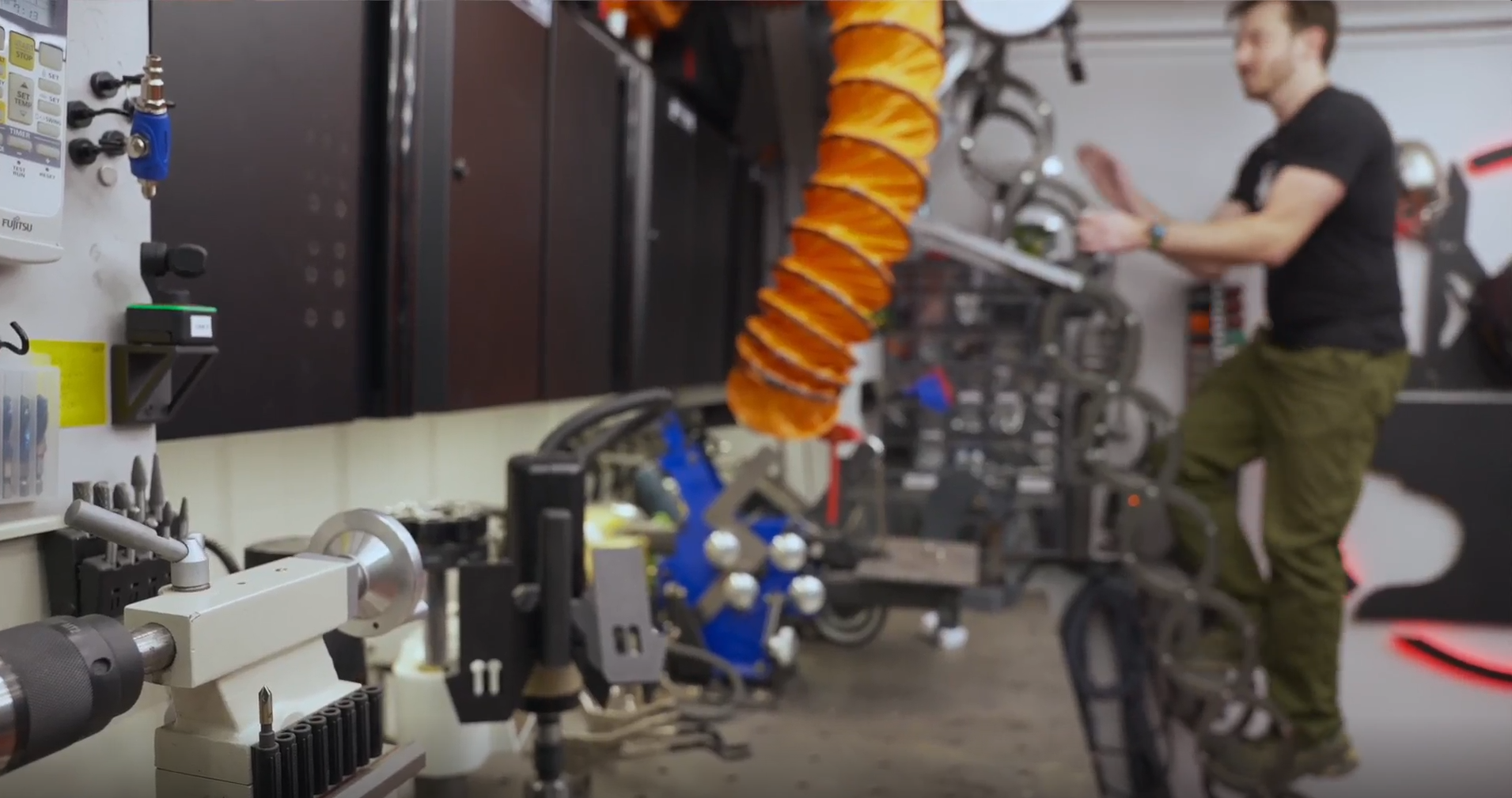

In a corner of the internet where science fiction routinely becomes working hardware, James Hobson (also known online as the Hacksmith) has spent the last three years building his dream R&D lab.

It’s dense with manufacturing tech: CNCs, welders, lasers, electronics benches, storage systems, and a full content studio with more than a dozen cameras. Every workstation is always “armed and ready” so he can move from idea to prototype in minutes, not days.

But the real magic isn’t just what’s in the room.

It’s how the room behaves.

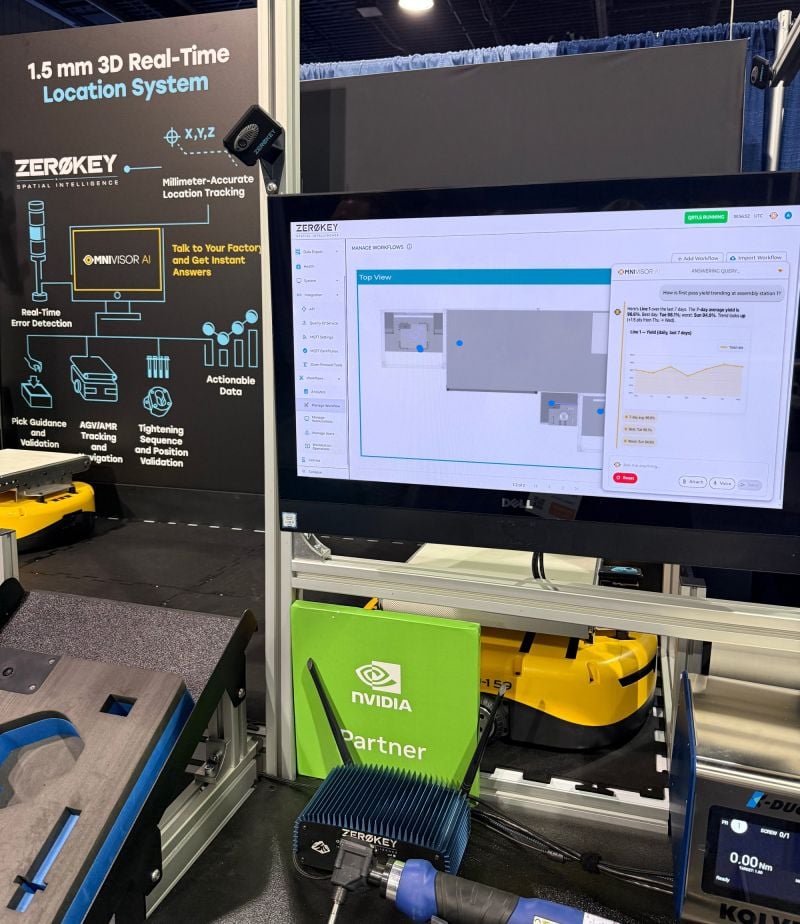

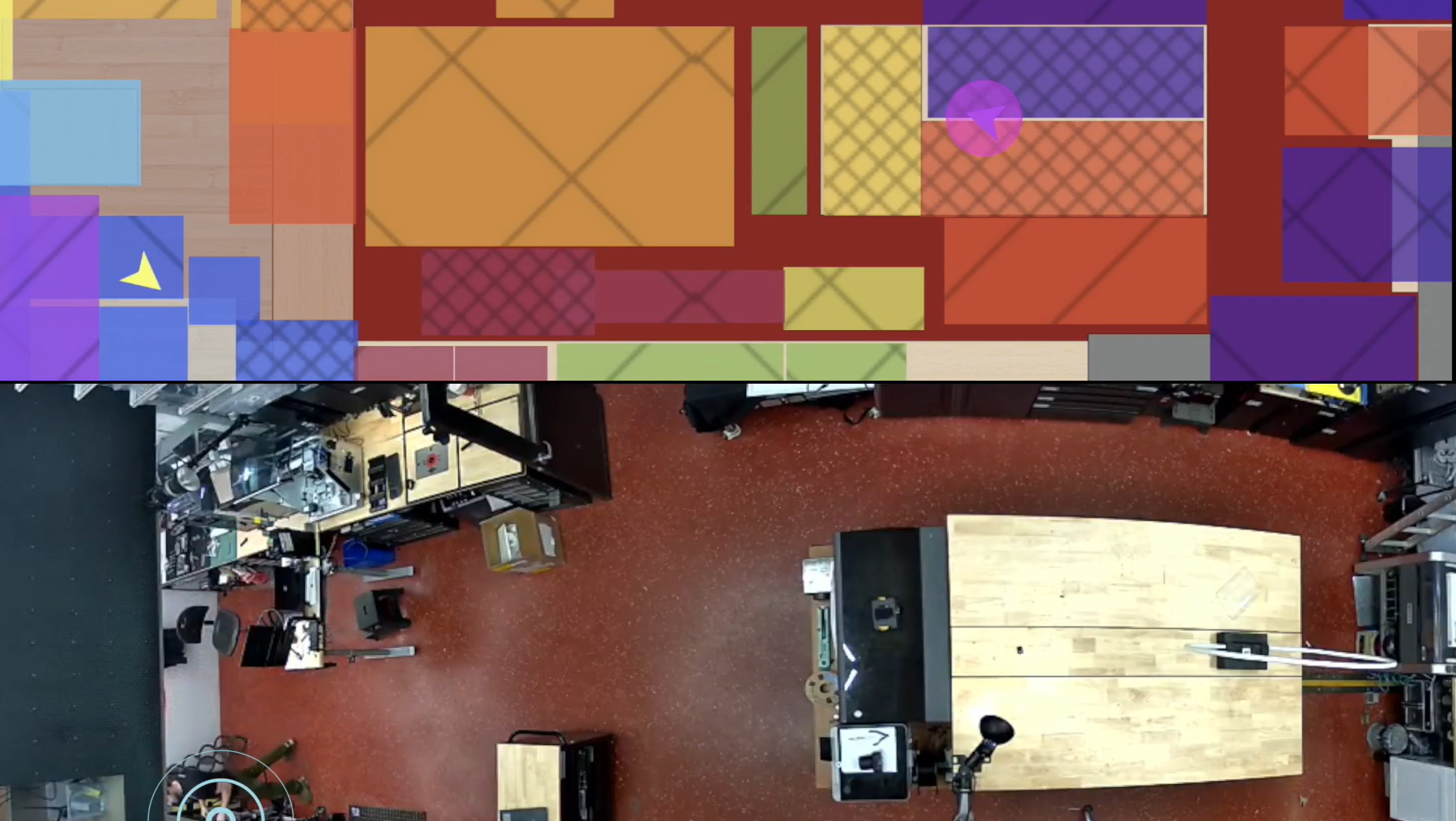

Using ZeroKey’s Quantum RTLS™ 2.0 platform, James has turned his lab into a space that tracks his movements in real time with 1.5 mm accuracy and responds automatically by moving cameras, changing recording scenes, and even coordinating with robotics and lighting.

He calls the system ZeroDOP: a lab that removes as much friction as possible between “I have an idea” and “it’s built and on camera.”

This article explores how that works and why this niche, creator-focused setup is a very powerful preview of what’s possible when you deploy our technology in modern industrial environments. The outcome is complete operational visibility and efficiency through an advanced physical AI platform (OmniVisor AI™) built on millimeter-accurate real-time location data.

The Hacksmith's ZeroDOP Lab in Action

A Lab That Follows the Creator

As James moves through his Hacksmith Industries lab, he wears a Quantum RTLS Wristband that continuously tracks his hand movements in 3D space with unparalleled precision.

Using the live position data from our system and the geofenced zones he’s configured around machinery and workbenches, he’s built a fully automated studio. Here’s what that looks like:

- When he walks to a station and starts working, the system detects his precise location and automatically moves and switches the cameras in his studio to frame the work area.

- When he climbs the ladder to his mezzanine desk, the cameras transition seamlessly to follow him up. If he sits down at his computer, screen recording is automatically added as a second angle.

- When he turns to another bench to prototype something, the system instantly switches to the right camera and angle, without him touching a tablet, keyboard, or clicker.

Behind the scenes, our Quantum RTLS 2.0 technology continuously streams James’s position and location events into his custom ZeroDOP control software, which talks to Open Broadcaster Software (OBS) and other studio tools to move and switch more than a dozen cameras placed throughout the lab in real time.

He’s extended this idea beyond using our tech to track only his cameras:

The Result

The lab itself handles the busywork of filming and switching angles, so James can stay focused on engineering and storytelling.

TRACK

A robotic lamp tracks his Quantum RTLS Wristbands, ensuring his work area is always illuminated

CONNECT

Devices across the lab are connected on a smart network, orchestrated by voice and the spatial context provided by the ZeroKey system

STREAMLINE

Storage, tools, and interfaces are all arranged to minimize “friction time” (i.e., the clicks, plugs, and setup steps that usually slow down real work)

For a content creator, that means the difference between “I should film this… later” and “just start building and it’ll be recorded.”

For an industrial environment, it’s a sneak peek into how spaces outfitted with the right technologies can understand where people are and what they’re doing, and then respond in real time.

From Creator Studio to Factory Floor: Why This Matters for Industry

At first glance, James’s use case looks niche: a hyper-accurate RTLS powering an automated YouTube studio.

But peel back the cameras and lights, and the outcome is exactly what leading manufacturers are looking for:

- An environment that understands human activity with millimeter-level precision and can adapt, assist, and optimize in real time.

Here’s how the same underlying capabilities translate directly to industrial operations:

1) Human-Centric Automation

In the ZeroDOP lab, the system doesn’t just know there’s “someone in this room.” It knows exactly where James is, which workstation he’s at, and what station he moved from.

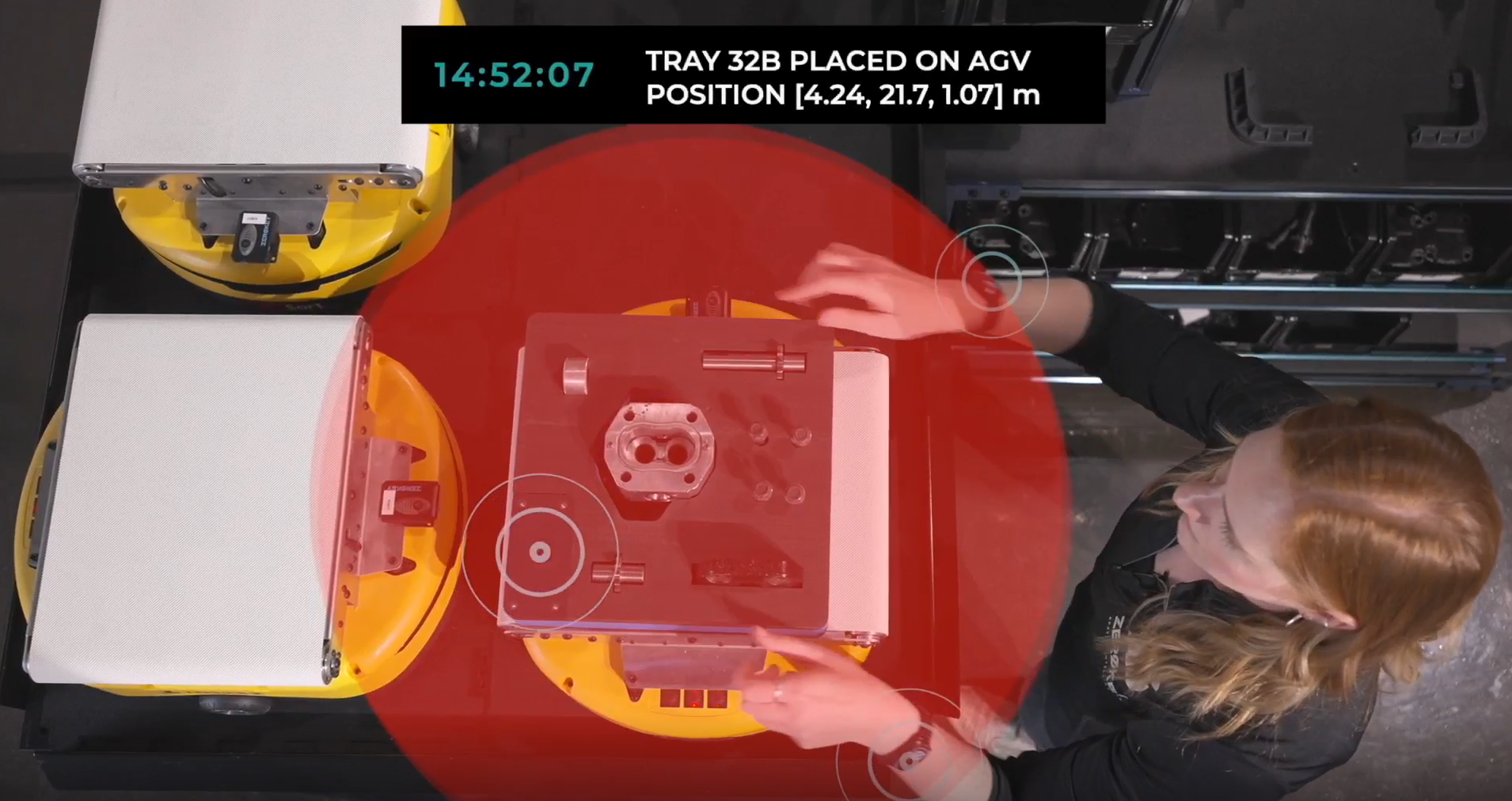

In a factory, that same precision enables:

Just-in-time assistive automation

- An AGV or AMR can move into position right as a worker completes their task, not minutes early or late.

- Carts, tools, or fixtures can be dispatched dynamically based on precise worker location and workflow stage.

Adaptive workstations

- Stations can auto-configure instructions, tools, and displays based on who stepped up and which product variant they’re handling.

- Safety interlocks and guidance can adjust based on exactly where a person is standing.

Instead of workers having to adapt to rigid systems, systems adapt to workers the same way James’s cameras adapt to him.

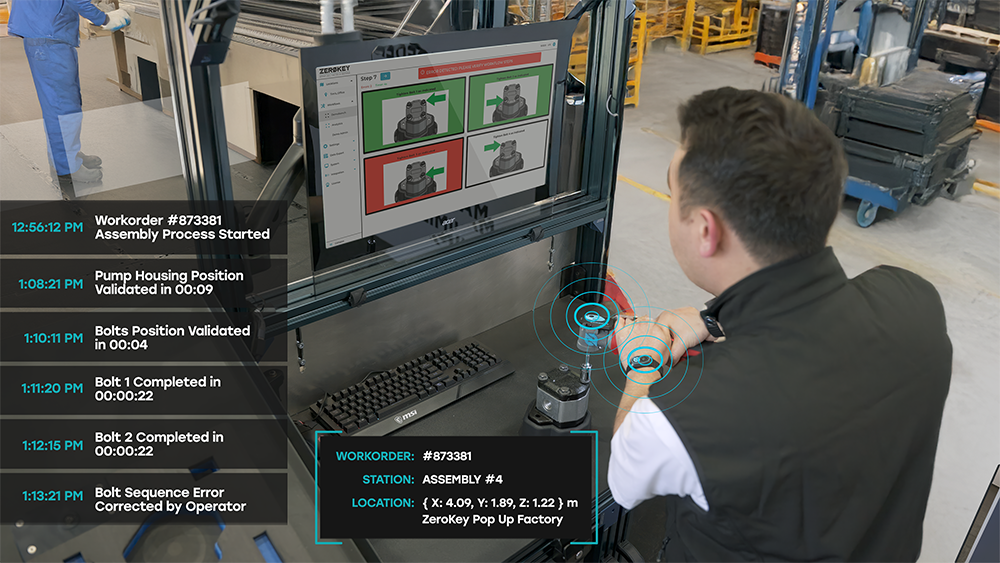

2) Millimeter-Accurate Digitization of People and Processes

Most legacy RTLS systems operate at meter-level resolution and low update rates. That’s fine for tracking pallets in a warehouse, but it’s nowhere near enough resolution to truly digitize human motion and detailed workflows. ZeroKey closes that gap by delivering continuous, millimeter-accurate 3D positioning across large spaces, unlocking a whole new class of analytics and control:

Workflow mapping at human scale

- See how workers move at a level precise enough to determine whether a tool is placed on the correct fastener or a part is picked from the correct bin.

- Identify micro-inefficiencies like extra steps, awkward reaches, and congestion points.

High-resolution cycle time and task segmentation

- Separate “value-add” activity from motion and waiting with sub-second granularity.

- Understand exactly where variation enters the process: which step, which location, which motion.

Safer human–robot interaction

- Robots, cobots, and AGVs can operate confidently closer to humans because the system knows exactly where those humans are, not just that they’re “somewhere nearby.”

In James’s lab, that precision keeps cameras and robots in sync with his movement. On a factory floor, it keeps entire production systems synchronized with human work.

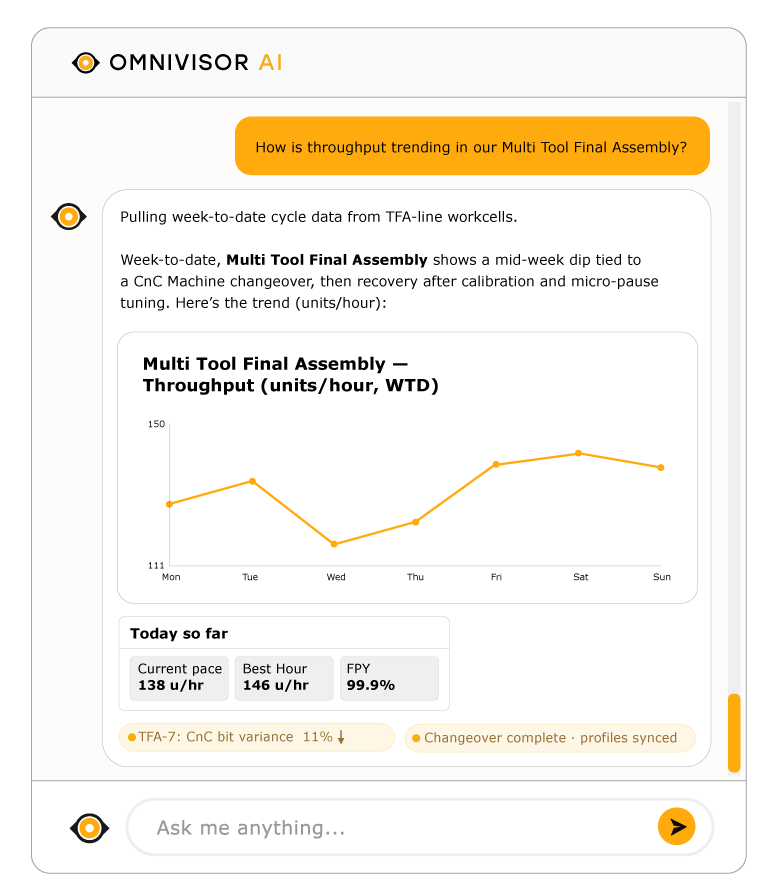

3) OmniVisor AI: Turning Location Data into Actionable Intelligence

Digitizing human motion and equipment position is only half the story. ZeroKey’s advanced physical AI platform, OmniVisor AI, connects the high-fidelity spatial data from Quantum RTLS with the rest of your operational ecosystem to provide real-time intelligence and insights in plain language.

Acting upon millimeter-accurate ground truth, the system can:

Detect bottlenecks and inefficiencies automatically

- OmniVisor AI can learn what “normal” looks like in your workflows and flag when motion patterns, dwell times, or hand-offs drift out of tolerance.

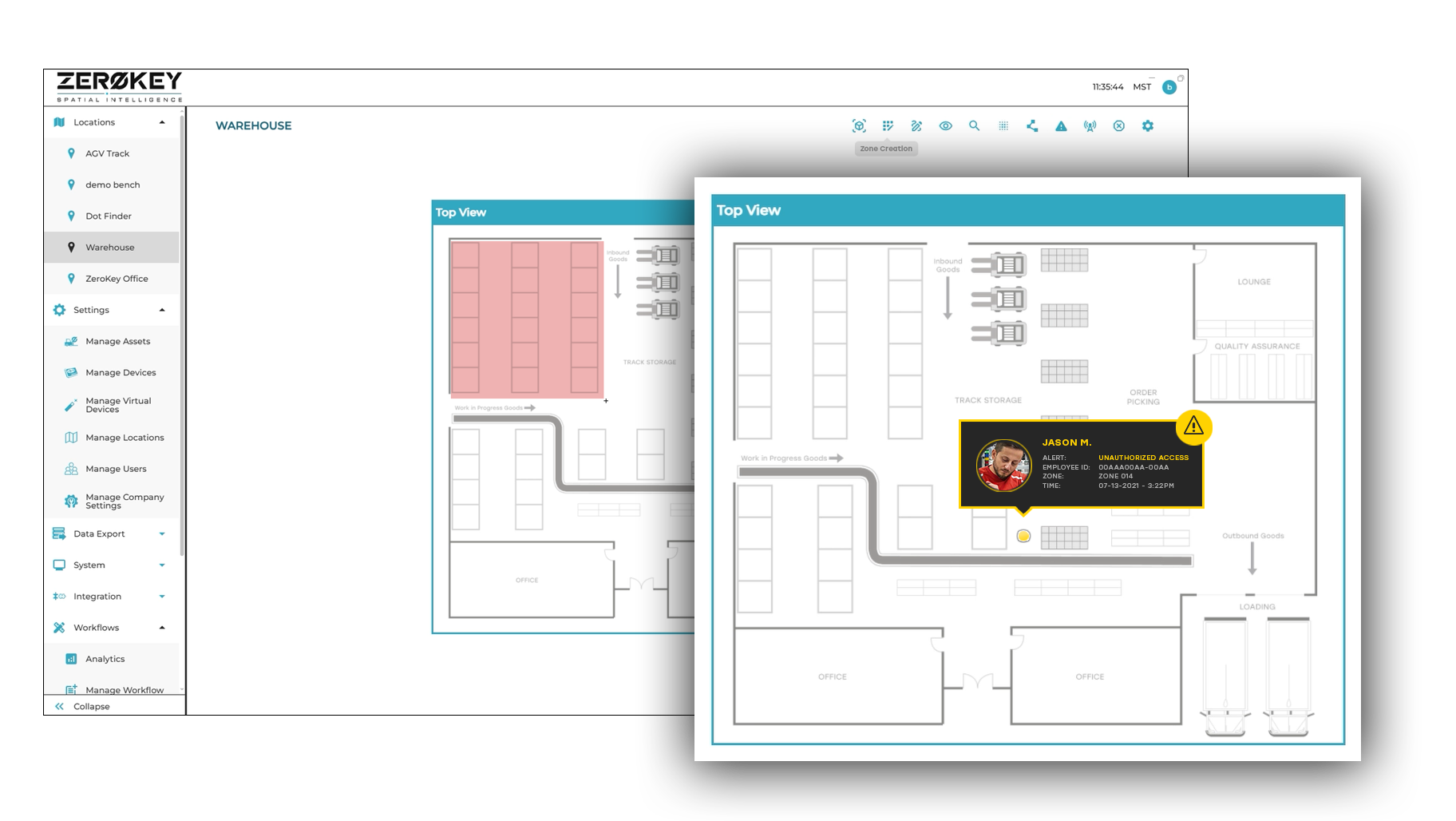

Trigger context-aware alerts and workflows

- If a worker enters a hazardous area without proper preconditions met, OmniVisor AI can trigger alarms, slow down a robot, or adjust a process.

- If a task is taking longer than expected at a particular station, it can notify supervisors with exact spatial context.

Optimize layouts and processes with evidence, not guesswork

- Replay a shift as a precise 3D “motion capture” of your facility.

- Test “what if” layout changes virtually before moving a single workstation.

For industrial customers, this becomes a continuous improvement engine driven by a factory that understands itself.

Reducing Friction Is the Real Superpower

One of the most powerful takeaways from James is his focus on friction and systematically removing:

- Extra clicks to start recording

- Time spent plugging in devices or pulling out equipment

- The cognitive load of managing cameras, tools, and interfaces while trying to focus on engineering

In his words, the goal is to:

“Remove as much friction as possible from the purpose of the environment.”

ZeroKey exists to do the same thing for industrial environments that ZeroDOP does for James’s studio:

- Make the environment aware of where people are and what they’re doing.

- Let the operations respond in real-time through automation and highly contextual spatial information.

- Use millimeter-accurate data and OmniVisor AI to continuously optimize your environment: save time, reduce waste, and maintain peak efficiency, all by simply asking.

Whether you’re building the next viral prototype on YouTube or assembling high-value industrial products, the pattern is the same: when your environment understands itself, everything gets faster, safer, and more intuitive.

What This Means for Manufacturers & Industrial Innovators

James’s lab might be a one-of-a-kind creator playground, but the capabilities behind it are production-ready today. With ZeroKey’s Quantum RTLS 2.0 and OmniVisor AI, industrial organizations can:

- Digitize people and processes with unprecedented fidelity

- Orchestrate automation around humans, not the other way around

- Derisk advanced automation by providing ground-truth spatial context to robots and AGVs

- Accelerate continuous improvement through high-resolution motion and workflow analytics

- Unlock human-responsive environments where work becomes smoother, safer, and more natural

James’s “superpower lab” is a glimpse of where the industrial world is headed: facilities that behave more like partners than static infrastructure.