Error-Proof Every Fastening Step with 1.5 mm

Position Validation

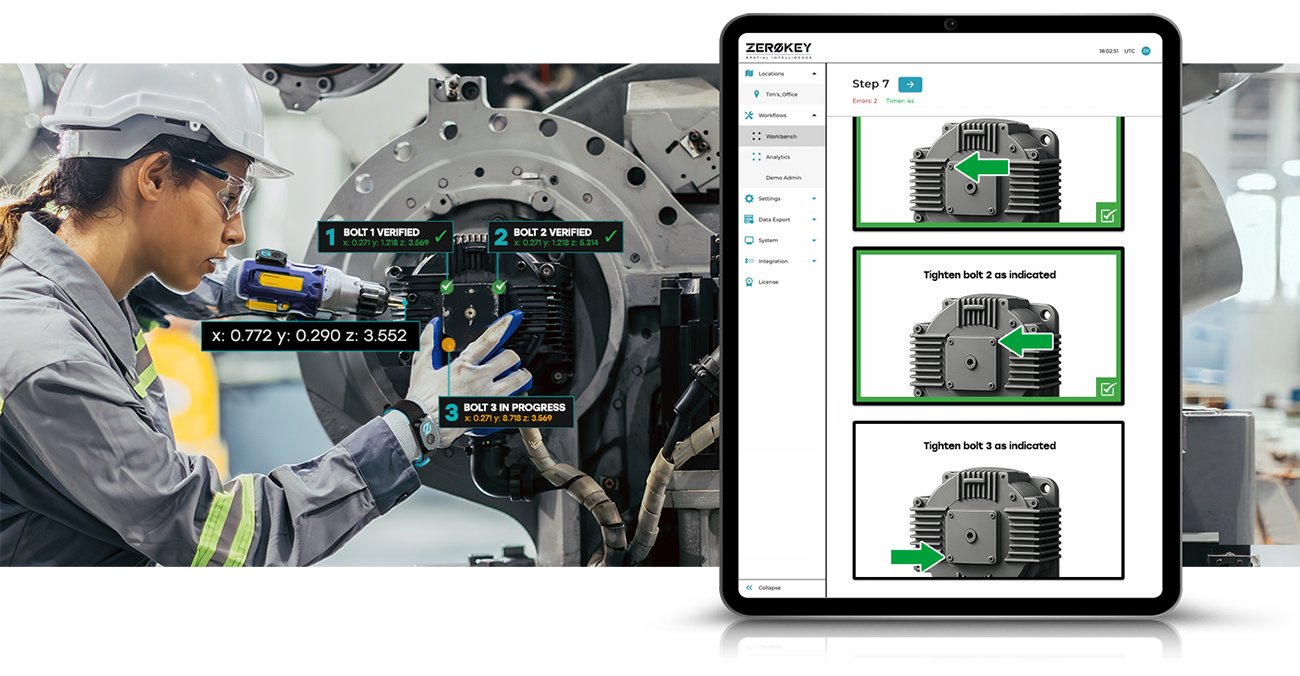

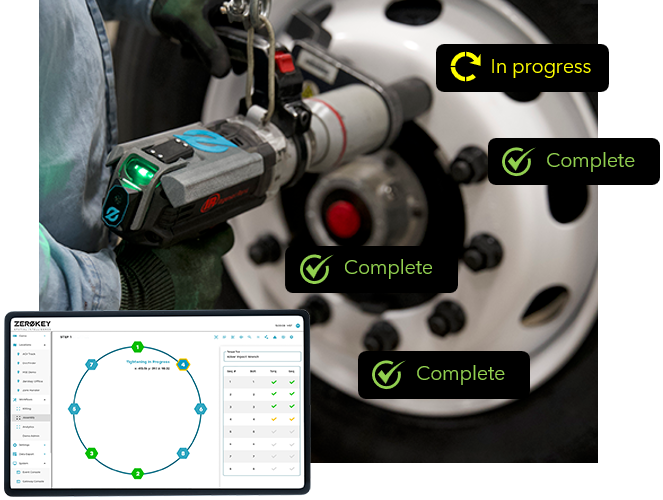

Eliminate missed or out-of-sequence tightening operations with millimeter-accurate real-time tool tracking. Quantum RTLS 2.0™ integrates with smart tools to enforce correct torque order and location automatically, eliminating rework, downtime, and waste from the manual fastening process.

The Problem

Tightening and fastening operations account for 40% of total defects in complex builds. Skipped or out-of-sequence tightening steps can lead to catastrophic in-the-field failures, especially for safety-critical assemblies.

The Solution

ZeroKey integrates hyper-accurate real-time location data with smart torque tools to enforce tightening locations and sequences, verify torque at every fastener, and ensure no steps are skipped. An optional tool lockout feature can also be enabled to eliminate assembly errors entirely.

Real-Time

QA/QC

Ensure bolts are tightened in the correct order and with the right torque, every time. Automated sequencing and immediate operator feedback guarantee process compliance every time.

Integrates with

Smart Torque Tools

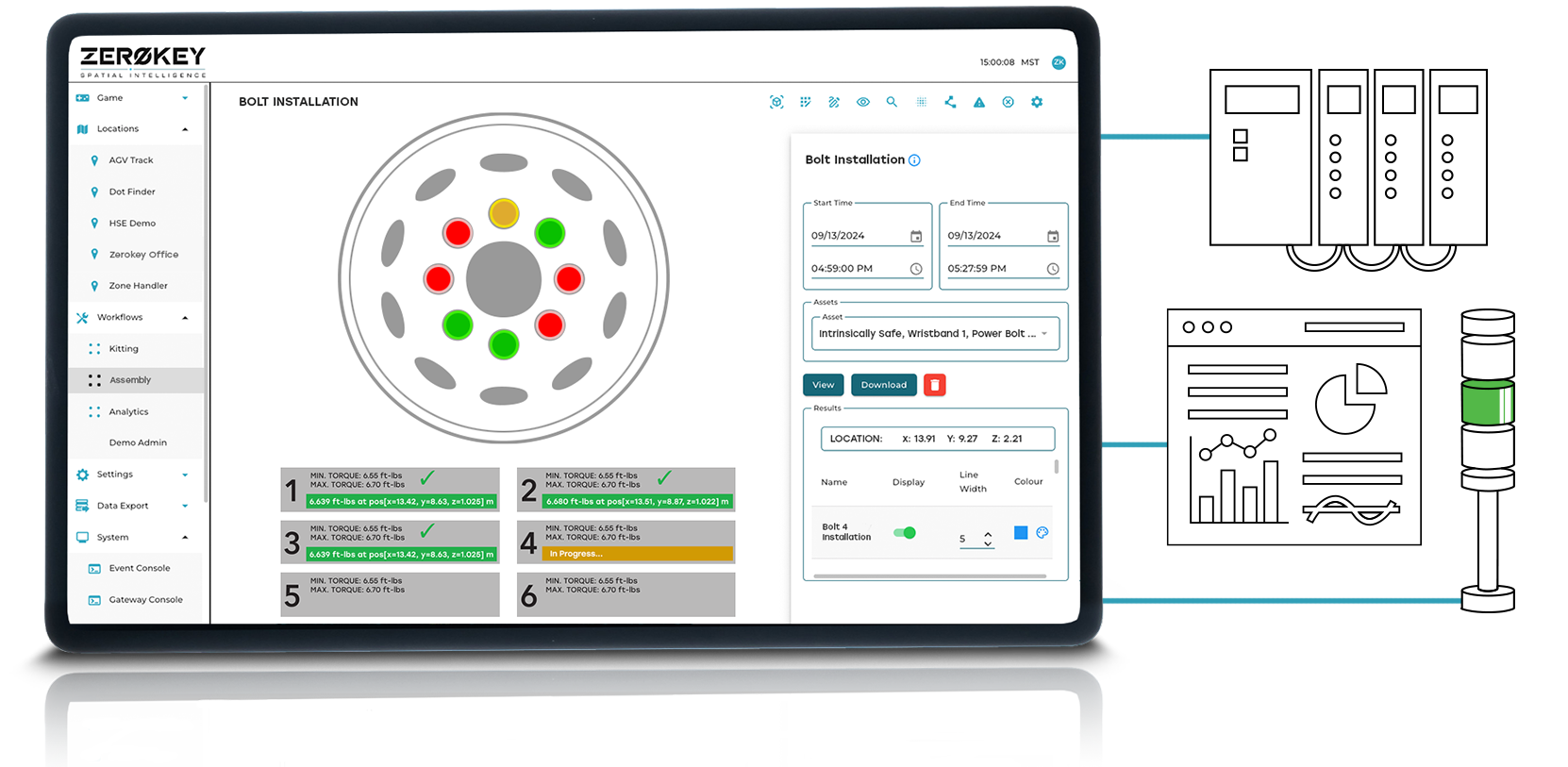

Quantum RTLS integrates with smart torque controllers, including Torque Open Protocol tools such as Atlas Copco, Cleco, Ingersoll Rand, Stanley-Black & Decker, Desoutter, and Kolver. An optional tool lockout feature eliminates operator bypass and ensures strict compliance with procedures.

Jig-less Bolt

Sequencing

Verify torque order and completion without static fixtures. ZeroKey maps bolt geometry dynamically to ensure no fastener is missed, regardless of where work takes place.

Audit-Ready

Traceability

Every torque event and position is automatically logged with 3D location and torque data, creating a complete digital record for instant verification and compliance audits.

Real-Time 3D Sequencing for Every Bolt

ZeroKey captures every torque event with millimeter accuracy, providing a live digital record of each tightening operation.

Use ZeroKey Workflows to enable live validation and tool control out of the box or connect through our API to stream spatial event data directly to your PLC, MES, or existing digital work instruction platform.

fetch("https://yourdomain.edge.zerokey.com/v3/modules/historian/workflowCompletions", {

method: "POST",

headers: {

"Content-Type": "application/json",

"Authorization": "Bearer <YOUR_ACCESS_TOKEN>"

},

body: JSON.stringify({

"StartTime": "2025-07-01T08:00:00Z",

"EndTime": "2025-07-01T18:00:00Z",

"StepTypes": ["BoltSequence"],

"IncludeStepData": true

})

})

.then(res => res.json())

.then(data => console.log("TaskID:", data.TaskID));{

"Timestamp": "2025-10-08T15:42:11Z",

"WorkflowID": "WF-TRK-042",

"StepType": "BoltSequencing",

"OperatorID": "E0:05:6E:B9:C1:0A",

"Status": "Completed",

"Bolts": [

{ "ID": 1, "TorqueNm": 320.4, "Status": "OK" },

{ "ID": 2, "TorqueNm": 322.1, "Status": "OK" },

{ "ID": 3, "TorqueNm": 319.7, "Status": "OK" },

{ "ID": 4, "TorqueNm": 318.9, "Status": "OK" }

],

"Summary": {

"CompletedBolts": 4,

"Missed": 0,

"OutOfOrder": 0,

"AvgTorqueNm": 320.7

}

}import paho.mqtt.client as mqtt

import json

BROKER = "yourdomain.edge.zerokey.com"

TOPIC = "zerokey/tools/torqueEvents"

TOKEN = ""

def on_message(client, userdata, msg):

data = json.loads(msg.payload)

print(f"{data['Timestamp']} | {data['ToolID']} | {data['TorqueNm']} Nm | {data['Status']}")

client = mqtt.Client()

client.username_pw_set(username="token", password=TOKEN)

client.connect(BROKER, 1883, 60)

client.subscribe(TOPIC)

client.on_message = on_message

client.loop_forever()

Simplify Industrial Integration

ZeroKey’s open API and MQTT interfaces make it easy to integrate spatial and torque data directly into your systems. Automatically log torque events, trigger workflows, or stream clean JSON data to your data lake without any extra infrastructure.

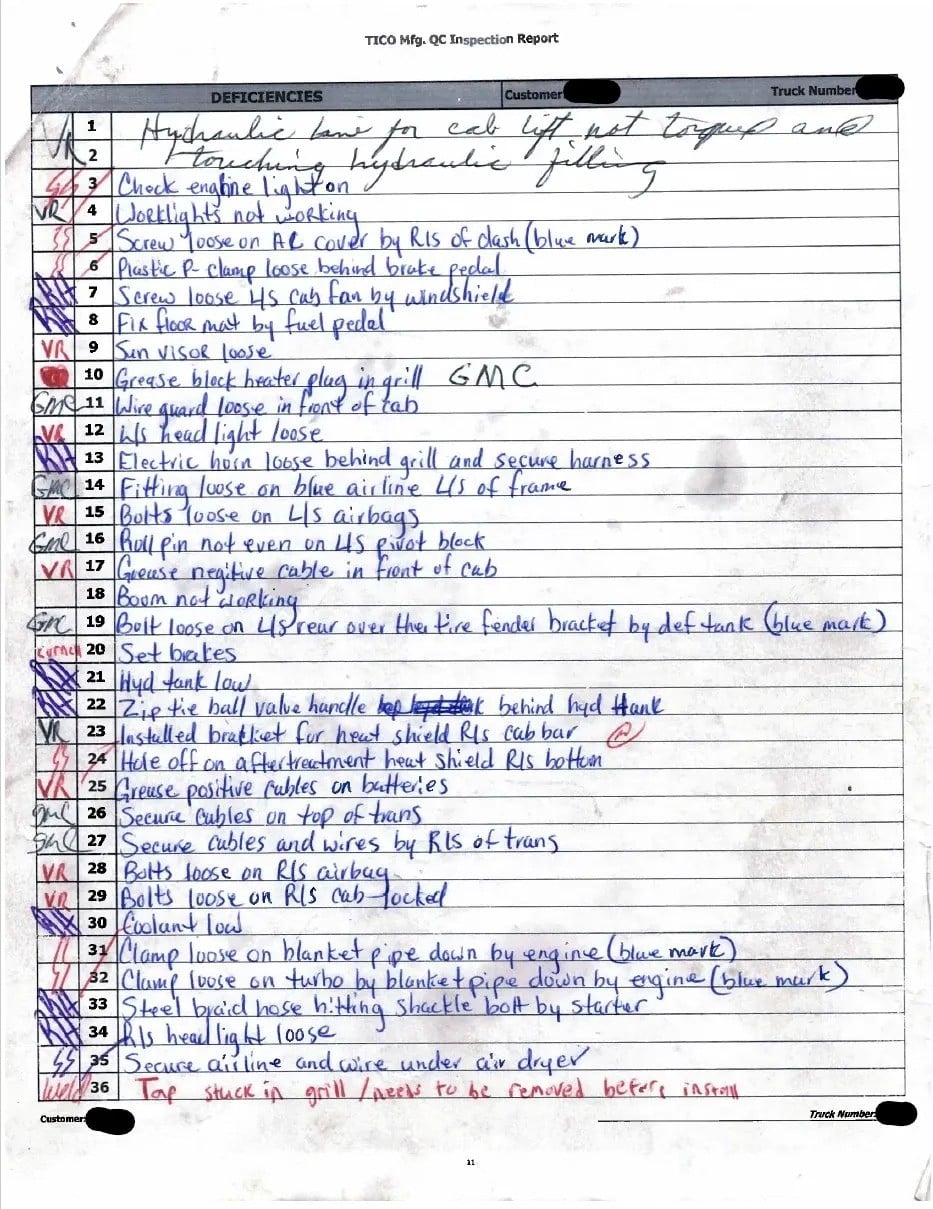

TICO Tractors Digitized Manual Processes, Slashing Rework and Inspection Time by 60%

The Challenge

One of TICO’s critical quality concerns was bolt-tightening during manual assembly, so they introduced smart tools to track the torque applied to each fastener. However, the team at TICO quickly realized the system was unable to identify exactly which bolt an operator was tightening due to the lack of precise 3D positioning.

The Solution

TICO deployed Quantum RTLS 2.0 in assembly cells, with tags mounted on the tools. Real-time workflow tracking with 1.5 mm accuracy matches torque events to specific fasteners, creating a digital record of completion for every truck.

The Impact

With Quantum RTLS 2.0, TICO achieved:

- • Exact Tool Positioning: Real-time spatial tracking at 1.5 mm accuracy pinpoints every torque event to it’s corresponding fastener.

- • Sequencing Verification: Each bolt is tightened in the correct order, with immediate alerts for skipped or repeated steps.

- • Torque Traceability: Integrated torque and position data create a complete digital record of every truck built.

- • Instant Feedback: Operators receive real-time guidance to correct errors without interrupting production.

By replacing reactive inspection with real-time verification, TICO shifted from quality control to full process assurance.

How It Works: Tool Tip Projection

Quantum RTLS 2.0 incorporates 6 degrees of freedom (6DoF) with 1.5 mm accurate real-time position to provide full spatial orientation of tools. This enables the system to project the exact contact point of the tool, capturing true interaction with each fastener.

Unlike vision systems that fail under obstruction, or other legacy RTLS limited to low-resolution 2D data, Quantum RLTS 2.0 delivers robust, live positioning in any environment.

WANT MORE INFO?

DOWNLOAD OUR WHITE PAPER

ZeroKey’s Quantum RTLS 2.0 technology is backed by more than thirty patents and extensive research and development! Want to learn why we’re the most accurate RTLS technology in the market? Read all about it in our white paper.

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3

RESOURCES

SITE MAP

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3