TICO Tractors Streamlined Manual Processes, Slashing Rework and Inspection Time by 60%

TICO Tractors Streamlined Quality Processes, Slashing Rework and Inspection Time by 60%

TICO's Beginnings

In 1980, TICO Tractors began searching for terminal tractors to add to their fleet, but they couldn’t find one they could count on. As a result, they began manufacturing their own, building powerful and reliable trucks that were comfortable and easy to maintain.

In 2008, TICO expanded its reach by introducing its equipment to the retail market, leading to a significant uptick in demand. With a unique approach of testing their equipment in real-world scenarios, TICO has consistently prioritized quality and efficiency in their manufacturing processes.

Since its beginnings in the 1970s, TICO has become North America’s largest terminal tractor fleet owner and operator.

From Manual Processes to Digitization

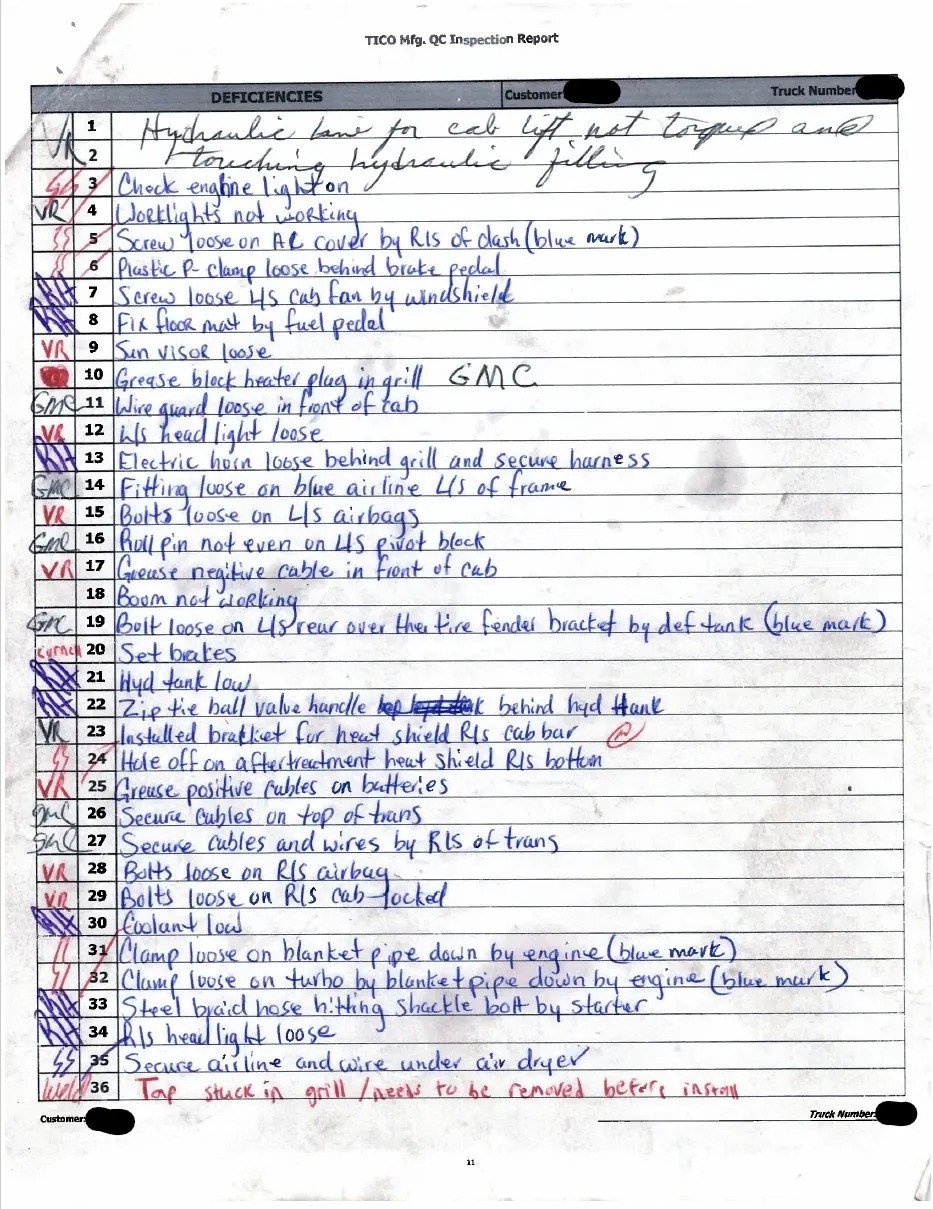

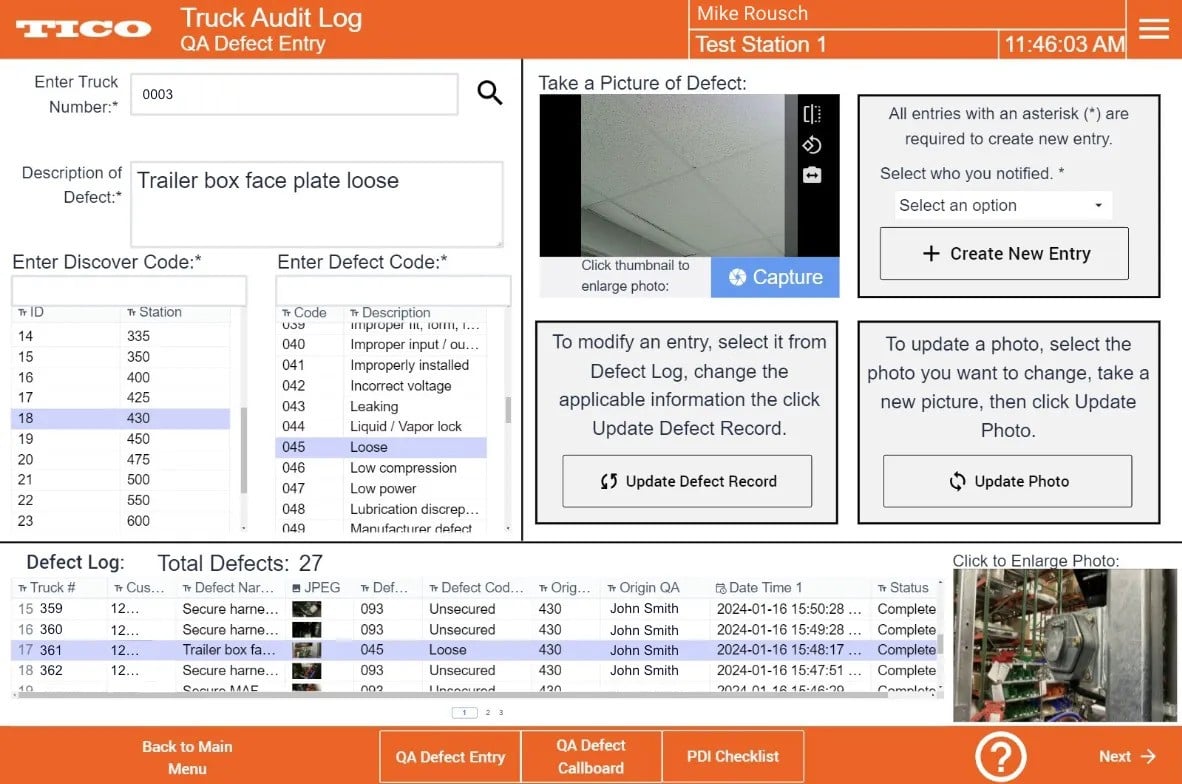

Historically, TICO relied on paper-based methods for quality inspections, standard operating procedures (SOPs), and production dashboards. As the company scaled, these manual processes became bottlenecks, leading to inefficiencies and increased potential for errors. Recognizing the need for modernization, TICO sought solutions that could digitize and streamline their operations without compromising their hands-on approach.

Ensuring Accurate Bolt Tightening Sequences

One of TICO’s key quality challenges was ensuring every bolt was tightened to the exact torque specification. They first introduced Ingersoll Rand tools to capture torque data for each fastener, but couldn’t confirm which specific bolt was being tightened. Vision systems were tested next, but without precise 3D positioning, closely spaced bolts made sequence verification difficult and inconsistent, often requiring secondary inspections.

To solve this problem, TICO implemented ZeroKey’s Quantum RTLS™, a cutting-edge location sensor technology that provides 1.5 mm 3D positioning accuracy in real-time. At the same time, TICO leveraged Tulip’s Frontline Operations Platform to create custom dashboards that visualize this high-precision spatial and torque data in real-time, right on the shop floor.

Together, this integrated solution enabled TICO to:

Precisely Track Tool Positioning: By attaching ZeroKey’s devices to torque tools, TICO can now monitor the exact location and movement of each tool during the tightening process.

Verify Bolt Sequencing: Quantum RTLS ensures bolts are tightened in the correct order according to predefined procedures by detecting and preventing (or immediately correcting) sequencing errors in real-time.

Integrate Torque Data: Hyper-accurate location data from the ZeroKey system is synchronized with torque values to immediately confirm whether each bolt has been tightened to specifications.

Provide Real-Time Feedback: Tulip dashboards display live alerts and updates based on the real-time spatial data from Quantum RTLS, enabling operators to correct any deviations on the spot, without needing to stop production.

This combined approach allowed TICO to move from reactive inspection to proactive quality assurance, fundamentally transforming how bolt tightening is monitored and validated.

Results: Enhanced Quality and Operational Efficiency

The implementation of Quantum RTLS and Tulip’s Composable MES yielded significant benefits for TICO, including:

A 60% Reduction in Inspection and Rework Time: Precise location data added an unprecedented level of traceability and quality assurance to TICO’s operations. With the real-time data seamlessly tracked in Tulip’s Frontline Operations Platform, the TICO team now has the data they need in a centralized location, enabling them to identify trends and uncover insights with a holistic view of their operations.

Increased Quality Control and Operational Efficiency: Consistent adherence to torque and sequencing specifications guarantees product reliability, ensuring confidence and proof that TICO delivers only high-quality products. Additionally, streamlined processes led to faster production cycles and reduced downtime.

Quantum RTLS: Bringing Hyper-Accurate Location Awareness to Manufacturing

By integrating ZeroKey’s industry-leading Quantum RTLS location sensor technology, the TICO team digitized day-to-day manual tasks, as well as their quality inspection and defect reporting processes, successfully addressing key challenges they faced in their operations. This collaboration not only improved product quality but also enhanced overall operational efficiency, reinforcing TICO’s commitment to innovation and excellence in manufacturing.

BOOK A SALES CALL

WANT MORE INFO?

DOWNLOAD OUR WHITE PAPER

ZeroKey’s Quantum RTLS 2.0 technology is backed by more than thirty patents and extensive research and development! Want to learn why we’re the most accurate RTLS technology in the market? Read all about it in our white paper.

RELATED ARTICLES

ZeroKey Selected by Volkswagen as a Top Exhibitor of Hannover Messe 2024

ZeroKey was honoured to be selected by Volkswagen as a top exhibitor of Hannover Messe…

Read more

Re-imagining the Operations Tech Stack with High-Accuracy Location Data

In today’s increasingly competitive world, businesses rely more than ever on an integrated and seamless…

Read more

10 Ways to Improve Manufacturing Operations with an RTLS

A real-time location system (RTLS) is an essential tool for businesses that want to improve manufacturing…

Read more

Empowering Frontline Workers through Digital Transformation

The Benefits of Empowering Frontline Workers with Digital Tools and Technologies Digital…

Read more

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3

RESOURCES

SITE MAP

CALGARY

HEAD OFFICE

3120 – 12 St. NE

Calgary, Alberta T2E 8T3